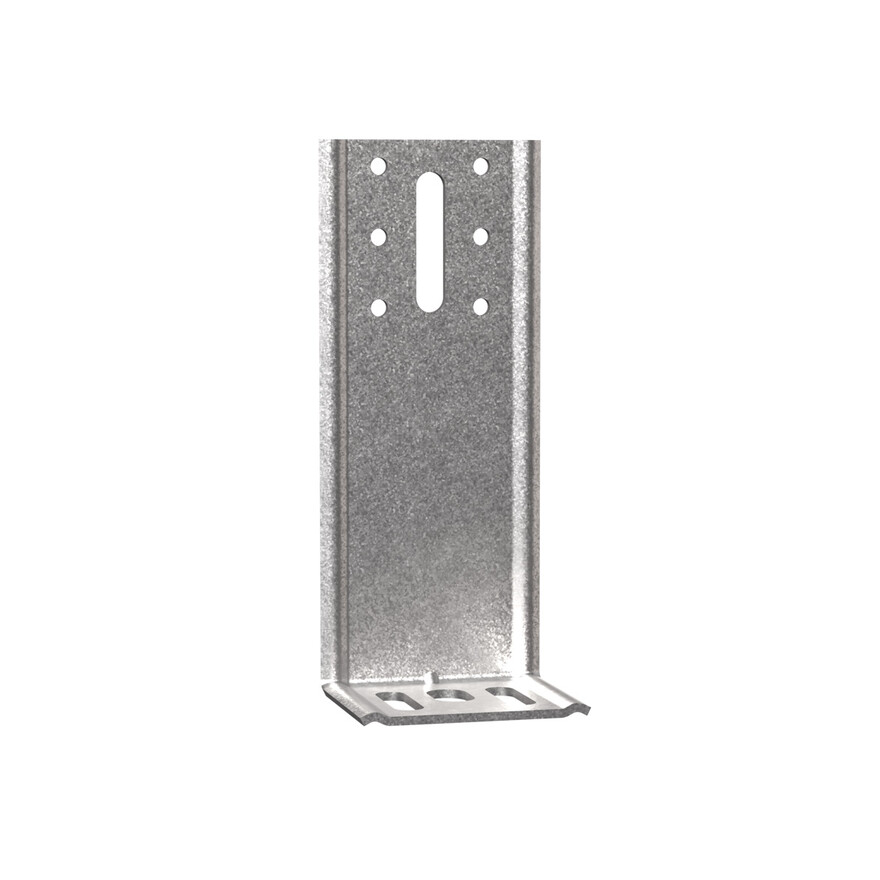

Angle bracket for cladding (previously ABC)

The EBC (previously ABC) angle bracket has been designed to fix vertical battens directly to the supporting structure without the need for additional battens, it creates a zone for insulation and/or ventilation between the wall and the cladding.

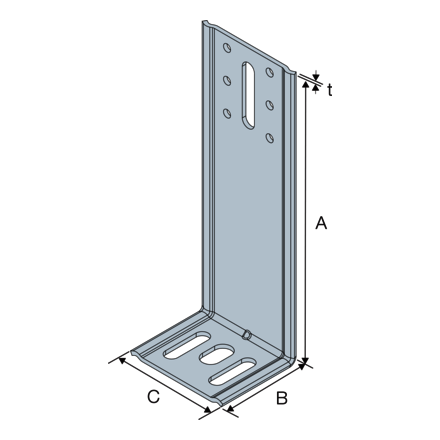

Product Details

Features

Material

- Pre-galvanised mild steel.

Benefits

- Connect vertical battens directly to the supporting structure.

- No need for horizontal battens.

- Creates a zone for insulation or ventilation.

- Reduces installation time, materials and cost.

- Suitable for cavities 50mm to 145mm.

Application

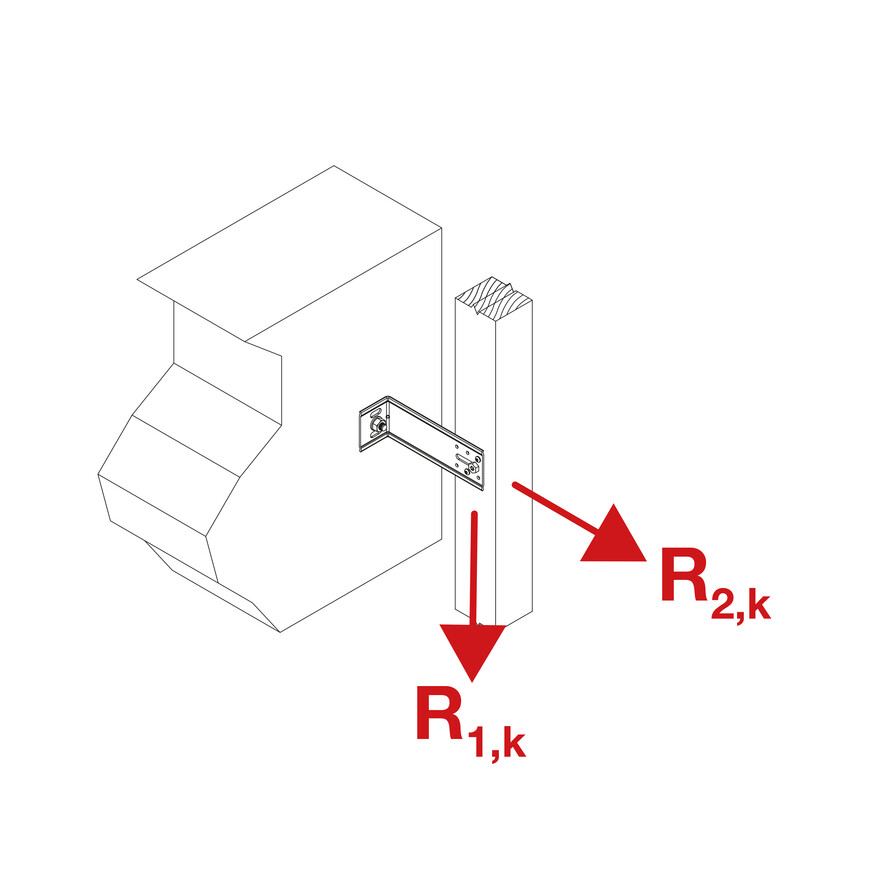

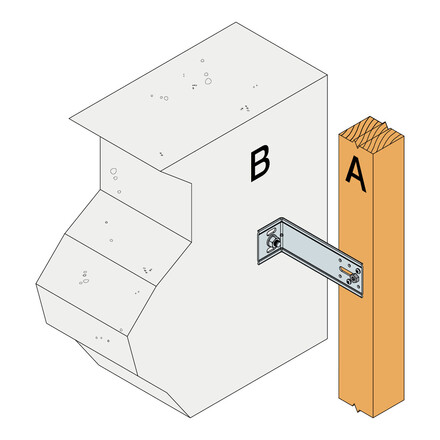

Header member

- Supporting member: concrete, masonry, etc.

- Supported member: solid wood, etc.

For Use With

- Fastening of battens for exterior cladding.

Technical Data

Product characteristic capacities - Timber to Concrete - 1 angle bracket per connection

| References | Product characteristic capacities - Timber to Concrete - 1 angle bracket per connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - 1 angle bracket per connection [kN] | ||||||||

| Flange A | Flange B | R1.k | R5.k | ||||||

| Qty | Type | Qty | Type | Qty | Type | 1 mm slip | 3 mm slip | ||

| EBC100/2.5 | 2 | CSA Ø5,0x40 | 1 | SSHØ8,0x40 | 1 | Ø8 | 0.22 | 0.36 | 1.56 |

| EBC120/2.5 | 2 | CSA Ø5,0x40 | 1 | SSHØ8,0x40 | 1 | Ø8 | 0.22 | 0.36 | 1.56 |

| EBC140/2.5 | 2 | CSA Ø5,0x40 | 1 | SSHØ8,0x40 | 1 | Ø8 | 0.18 | 0.31 | 1.56 |

| EBC160/2.5 | 2 | CSA Ø5,0x40 | 1 | SSHØ8,0x40 | 1 | Ø8 | 0.18 | 0.31 | 1.56 |

| EBC200/2.5 | 2 | CSA Ø5,0x40 | 1 | SSHØ8,0x40 | 1 | Ø8 | 0.07 | 0.19 | 1.56 |

| EBC210/2.5 | 2 | CSA Ø5,0x40 | 1 | SSHØ8,0x40 | 1 | Ø8 | 0.07 | 0.19 | 1.56 |

Note - Slip under load measured at extremety of bracket

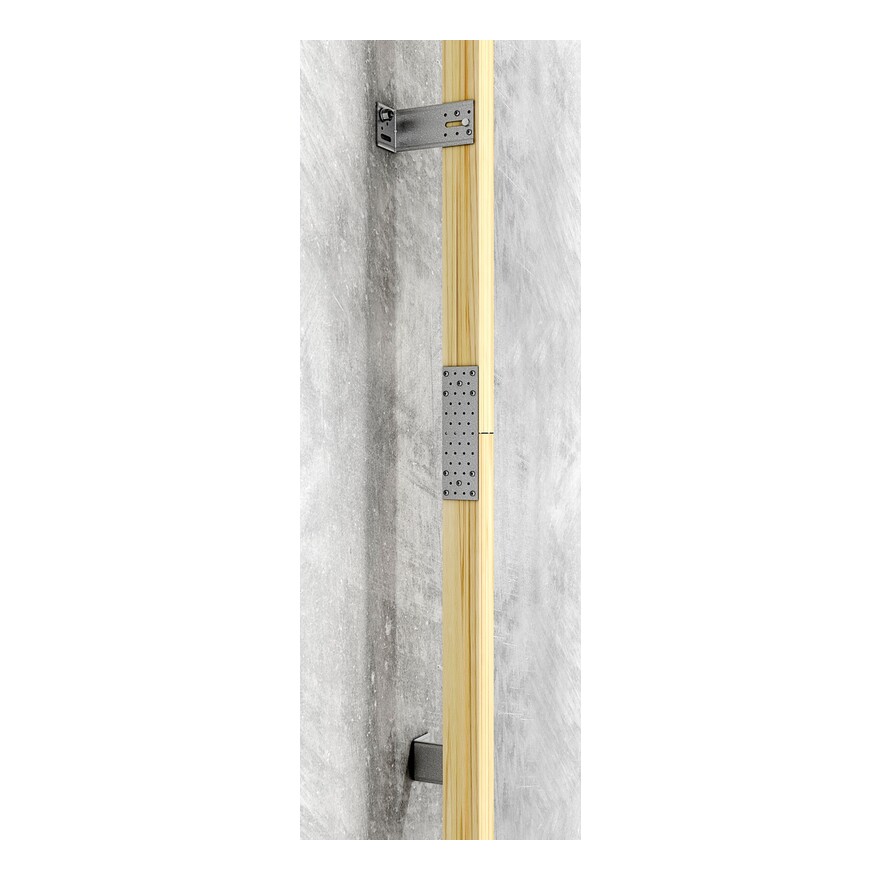

Installation

Installation

Fixing

Drill holes: Number and diameter, see table of dimensions.

- Wood rafters : 1 SSH8x40 + 2 CSA 5x40 screws.

- Concrete substrate : FM753 6x65 anchor (75320C0606500) or mechanical anchor HIPC 8-60/20

- Hollow masonry substrate : chemical anchor: AT-HP or POLY-GP resin + LMAS M8-95/20 threaded rod + SH M16-130 screen.

Installation

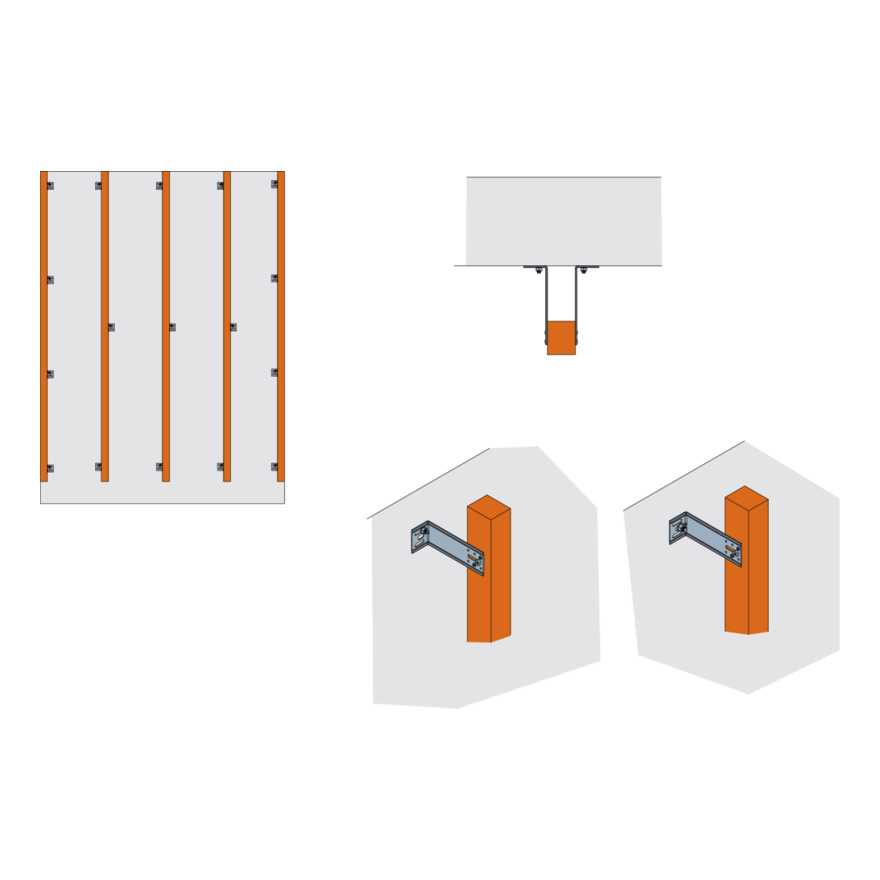

In standard sections, the standard installation consists of positioning the vertical rafters with a 60 cm spacing.

These rafters are fastened with angle brackets arranged in a staggered manner on either side of the rafter every 1.35 m, i.e., 1.23 angle brackets/m².

On the edges of the building, the spacing between the angle brackets is reduced (0.90 m)and the angle brackets are all placed on the same side on the end rafter (see diagrams). The rafter is fastened onto the angle bracket by a lag screw dia. 8 mm (placed in the obround hole dia. 8 x 40 mm centre) and by 2 additional screws dia. 5 mm to ensure the "anti-rotation" of the rafter. The angle bracket is fastened onto the concrete supporting member with an anchor dia. 8 mm placed in the top most obround hole dia. 8.5 x 30 mm.