CLT and Mass Timber for Industry

Partner for Success

with Simpson Strong-Tie

In order to provide the best solutions for the CLT and mass timber industry, it is important to have strong and reliable partnerships. At Simpson Strong-Tie we see it as our duty to provide the fastening solutions, support and services that can help your business deliver better and stronger solutions.

Related Content

Catalogues

Creating Value for Your Customers

‘No-Equal’ Standard and Custom-made products and components

At Simpson Strong-Tie we have a long history of designing and manufacturing custom made products and components for our industry partners. Sometimes a slight modification of a standard range product can be enough for it to fit seamlessly into the specific manufacturing of building components and sometimes we need to create a new design to solve the challenge.

We start out by discussing the challenge at hand with you, and then we find the best solution together. Thereby, we can create a custom made product, which not only solves your challenge, we can also design it taking the advantages of our manufacturing machinery into consideration, and thereby creating the most cost-effective solution for all parties involved.

Links

Local and Reliable

Local availability, reliable delivery - ready when you are

Simpson Strong-Tie has manufacturing and warehouse facilities across all of Europe. You will be able to work with local Simpson Strong-Tie people who are aware of the local needs and requirements.

When we enter into a partnership with you, finding the right logistic setup is crucial for us. This can be tailor-made to fit your needs to ensure that you have the right components, at the right place, at the right time.

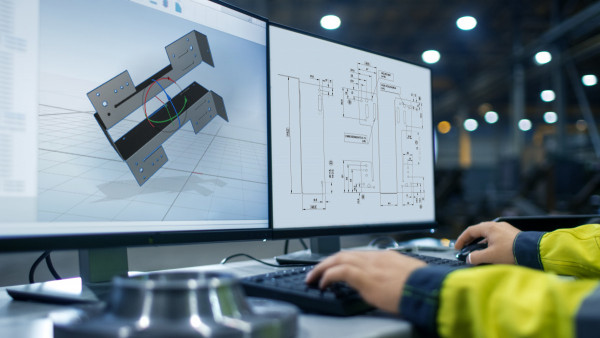

Everything We Know - You’ll Know

The best advice in town is never out of reach

If you are working with mass timber construction, our digital tools including: design software, design guidance, CAD models and product selection support are freely available on-line.

Coupled with this, we offer local support from our engineering teams across Europe, putting you in touch with the very people who design Simpson Strong-Tie products.

Join us at the top of the learning curve from the get-go.

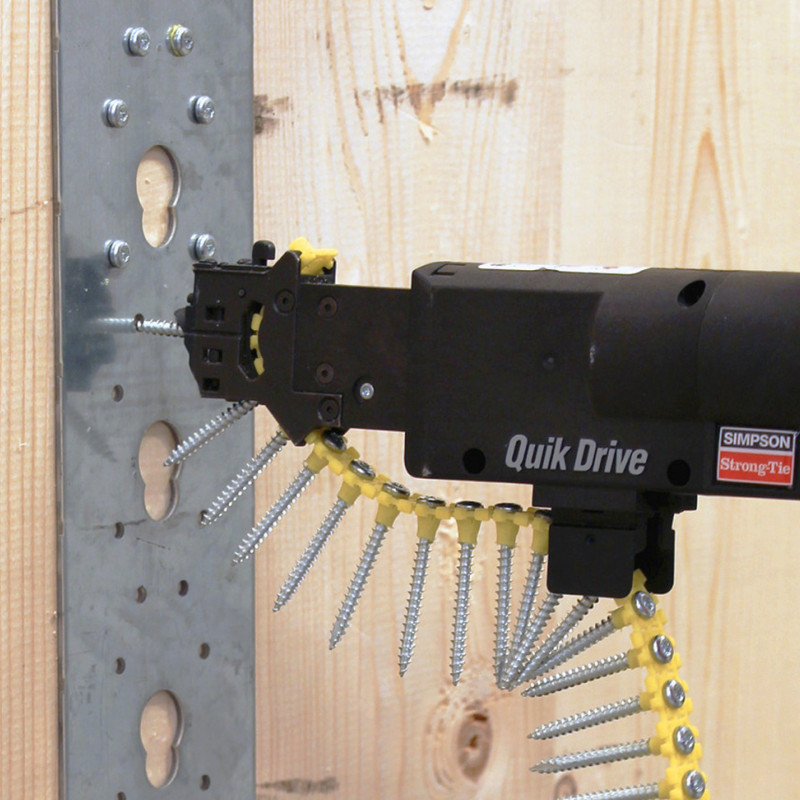

Faster Assembly - Quik-Drive®

Fastening has never been as fast or as cost-effective

Collated-screw fastening tools are replacing traditional nail guns for their speed, reliability and power. Quik Drive® auto-feed screw driving systems are easy to use, durable and designed for a wide variety of fastening applications.

Featuring quick-loading screw strips, precise countersink adjustment and a patented auto-advance mechanism. Save time and expense with CLT and mass timber structure assembly.

Nature Inspiring Technology

In this short film, NCC Production Manager, Mads Seirup Rasmussen explains:

"I am standing at a construction site in Odense. It is called the Cobot Hub. The special thing about this construction is that the primary building material is wood, both in terms of columns, beams and CLT panels. The connections of the CLT panels to the beams are made with structural screws supplied by Simpson Strong-Tie and specified by our engineer and timber supplier.The screws, that are 360mm in length are screwed vertically down into the beams. The structural screws fully comply with our expectations. Not least because we don't have to pre-drill, which is a big benefit that makes our job significantly easier.

Since I started my search for these structural screws, I have had a regular contact person with Simpson Strong-Tie, whom I made great use of. I have been able to get the needed screws and when we needed more special screws, they have been very helpful in order to deliver quickly. And even though they might not be in stock locally, they have supplied them form Germany.

For me it has been nice to know that when I make an order, the screws are supplied within a short timeframe.

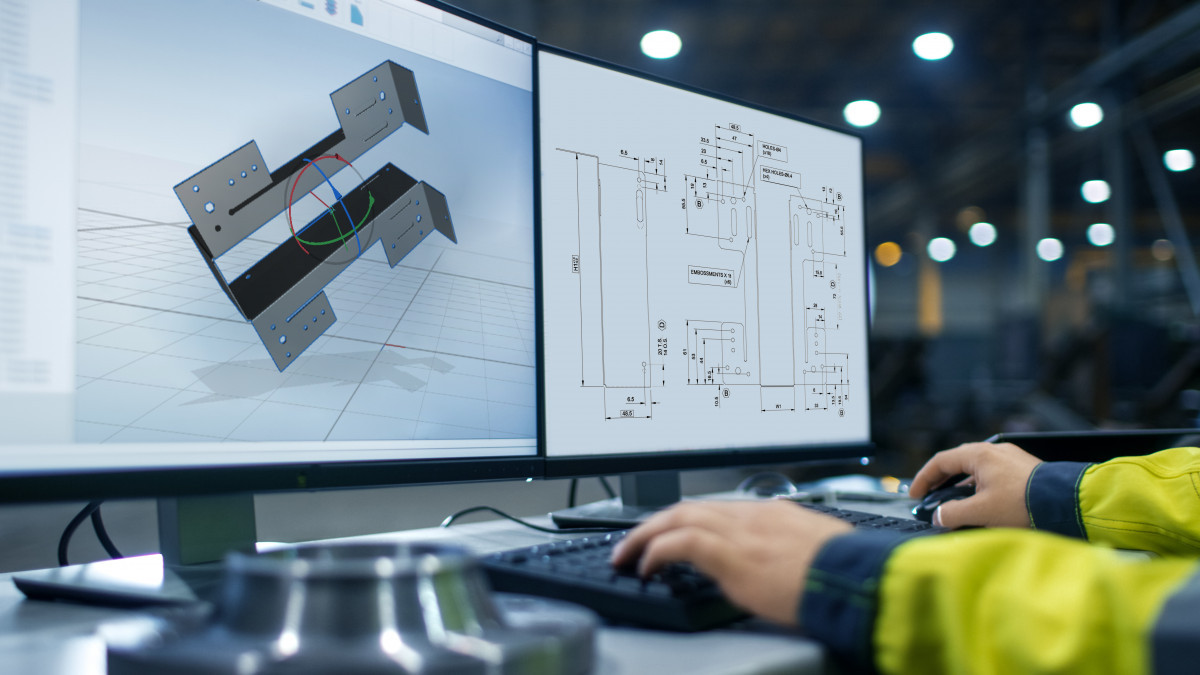

Fast, accurate and safe product specification

Solid Wood is our latest web-based calculation tool that helps consulting engineers, building designers etc. with finding and documenting the right fastening solution.

The program is easy to use, and makes it easier to understand and specify the right solutions, based on e.g. the density of the substrate, the characteristics of the material, the category of corrosion and the load. In 4 simple steps, Solid Wood finds a concrete fastening solution that is suitable for the specific project. The specifications can be printed out and used as documentation.

- Documentation according to Eurocode 5 (EN 1995-1-1)

- Faster and easier than hand counting

- Wood-wood / steel-wood / plate-wood joints

- The program creates a PDF report which can be used to document the project.

Links

Contact our Engineered Products Division

For general enquiries contact our sales support team:

Tel: 01827 255600 (option 1 + 1)

Email: epdsales@strongtie.comFor technical support:

Tel: 01827 255600 (option 2)

Email: uktechnical@strongtie.com