General Purpose Resin Mortar

Chemical anchor for use in concrete and masonry. Specially formulated for light or medium duty fixing into hollow or solid base materials.

Poly-GP300 is easy to use and fast curing, it enables good performance when used in applications such as fixing architectural steel work, cable trays, hand rails and gates.

Product Details

Features

Material

- Styrene free polyester

- Use with Simpson Strong-Tie threaded rod (LMAS) : galvanised steel and stainless A4-70

Benefits

- Fast curing.

- Non-flammable.

- Low odour.

- Colour changes when cured.

Application

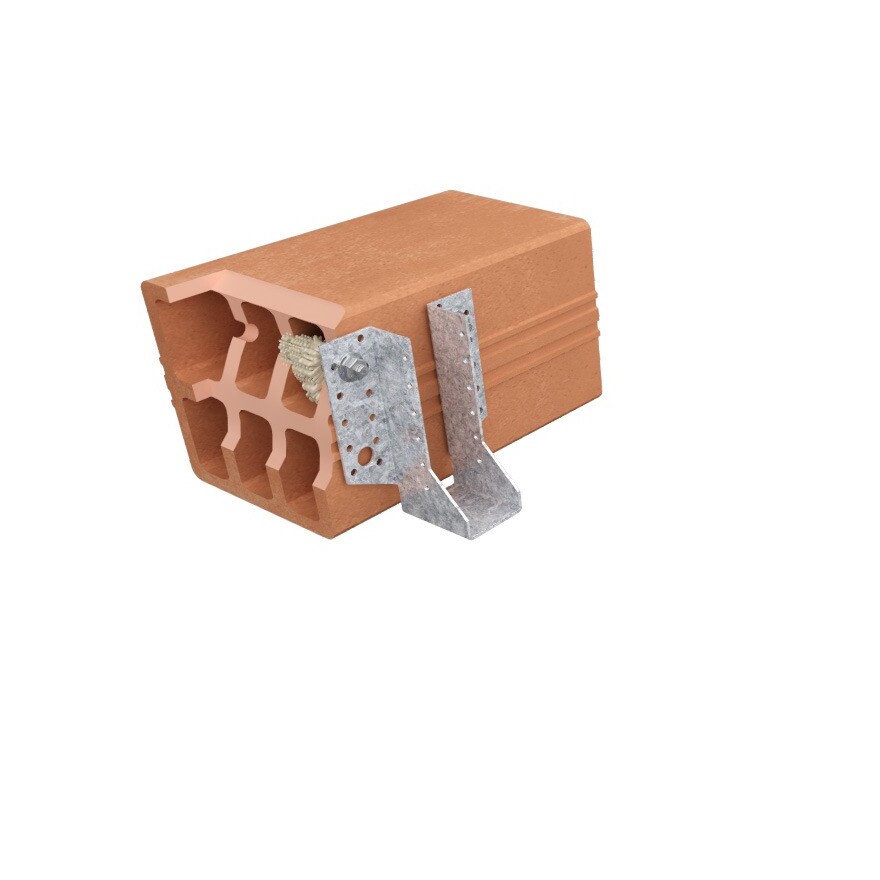

Header member

Hollow or solid masonry.

For Use With

- Blinds

- Hinges

- Air conditioners

- Satellite Dishes

- Boilers

Discontinued Products

Variant Status Details

Technical Data

Item Codes

| References | Color | Content [ml] | Weight [kg] |

|---|---|---|---|

| Poly GP + LMAS M10* | - | - | - |

Two nozzles are supplied with each cartridge. Downloadable Safety Data Sheet available from www.strongtie.eu

Performance Values

| References | Tension [Rds,N] [kN] | Shear [Rds,V] [kN] | ||||||

|---|---|---|---|---|---|---|---|---|

| Solid Brick | Autoclaved aerated concrete blocks | Hollow Brick | Hollow concrete block | Solid Brick | Autoclaved aerated concrete blocks | Hollow Brick | Hollow concrete block | |

| Poly GP + LMAS M10* | 0.72 | 0.35 | 0.43 | 0.35 | 0.72 | 0.35 | 0.43 | 0.35 |

Performance values are calculated from published data characteristic values in the ETA on which partial safety factors from ETA and a partial coefficient = 1.4 ɣf actions are applied. Service charges include the sealing position in the holder and is adhered to the method of installation. For hollow brackets unknown resistance, site of trials are needed (in accordance with ICASA recommendations for use by construction professionals for the construction of ankles tests on site).

Installation

Installation

Curing Schedule

| Temp of Support | -5°C | 0°C | 5°C | 10°C | 15°C | 20°C | 30°C |

| Working Time | 25min | 15min | 12min | 8min | 7min | 4min | 2min |

| Curing Time | 4h | 3h | 2h30 | 1h15 | 55min | 30min | 20min |

Solid Brick Installation

| References | Ø drilling diameter [d0] [mm] | Maximum diameter of hole in the fixture [df] [mm] | Depth of the drilling hole [h1] [mm] | Wrench Size [Sw] | Installation Torque [Tinst] [Nm] | Depth of the drilling hole [hef] [mm] | Characteristic spacing - Scr,N [mm] | Minimum spacing - Smin [mm] | Characteristic edge distance - Ccr,N [mm] | Minimum edge distance - Cmin [mm] |

|---|---|---|---|---|---|---|---|---|---|---|

| Poly GP + LMAS M10* | 12 | 12 | 85 | 15 | 6 | 80 | 200 | 50 | 100 | 50 |

Cellular Concrete

| References | Ø drilling diameter [d0] [mm] | Maximum diameter of hole in the fixture [df] [mm] | Depth of the drilling hole [h1] [mm] | Wrench Size [Sw] | Installation Torque [Tinst] [Nm] | Depth of the drilling hole [hef] [mm] | Characteristic spacing - Scr,N [Nm] | Minimum spacing - Smin [mm] | Characteristic edge distance - Ccr,N [mm] | Minimum edge distance - Cmin [mm] |

|---|---|---|---|---|---|---|---|---|---|---|

| Poly GP + LMAS M10* | 12 | 12 | 85 | 15 | 3 | 80 | 200 | 50 | 100 | 50 |

Foundation Brick

| References | Ø drilling diameter [d0] [mm] | Size of the Sieve | Maximum diameter of hole in the fixture [df] [mm] | Depth of the drilling hole [h1] [mm] | Wrench Size [Sw] | Installation Torque [Tinst] [Nm] | Depth of the drilling hole [hef] [mm] | Characteristic spacing - Scr,N [mm] | Minimum spacing - Smin [mm] | Characteristic edge distance - Ccr,N [mm] | Minimum edge distance - Cmin [mm] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Poly GP + LMAS M10* | 16 | 16x85 ou 16x130 | 12 | 135 | 15 | 6 | 130 | 500 | 100 | 250 | 100 |

Hollow Cinderblock

| References | Ø drilling diameter [d0] [mm] | Size of the Sieve | Maximum diameter of hole in the fixture [df] [mm] | Depth of the drilling hole [h1] [mm] | Wrench Size [Sw] | Installation Torque [Tinst] [Nm] | Depth of the drilling hole [hef] [mm] | Characteristic spacing - Scr,N [mm] | Minimum spacing - Smin [mm] | Characteristic edge distance - Ccr,N [mm] | Minimum edge distance - Cmin [mm] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Poly GP + LMAS M10* | 16 | 16x130 | 12 | 135 | 15 | 6 | 130 | 500 | 100 | 250 | 100 |