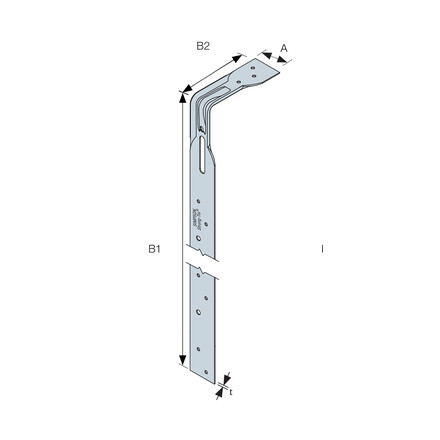

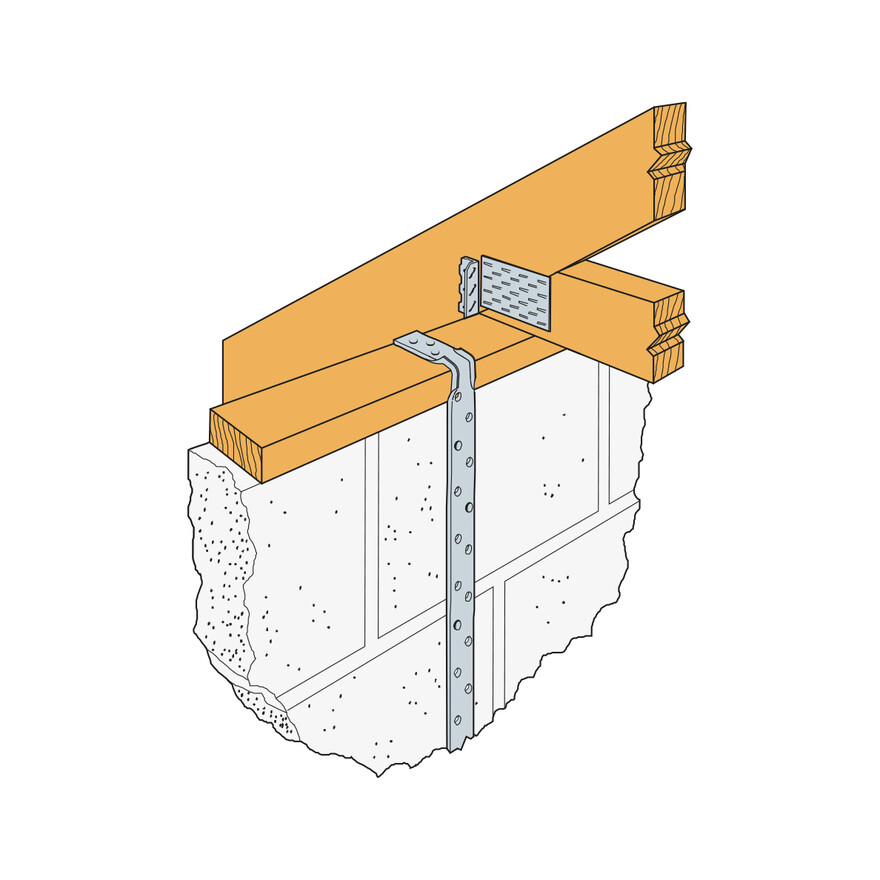

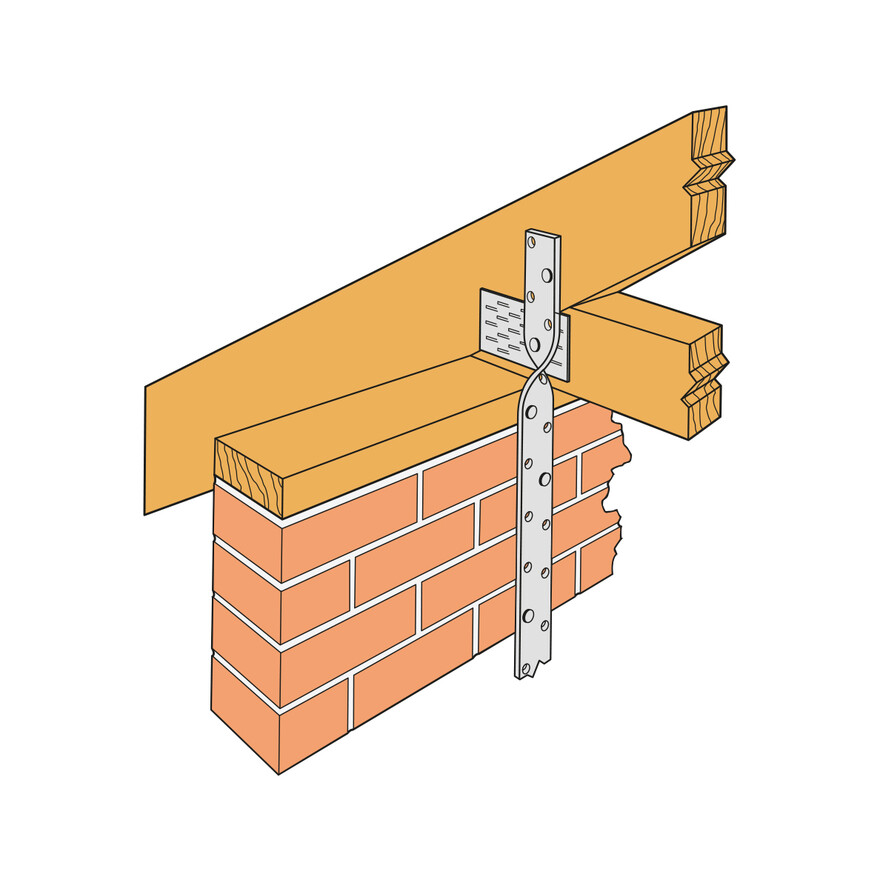

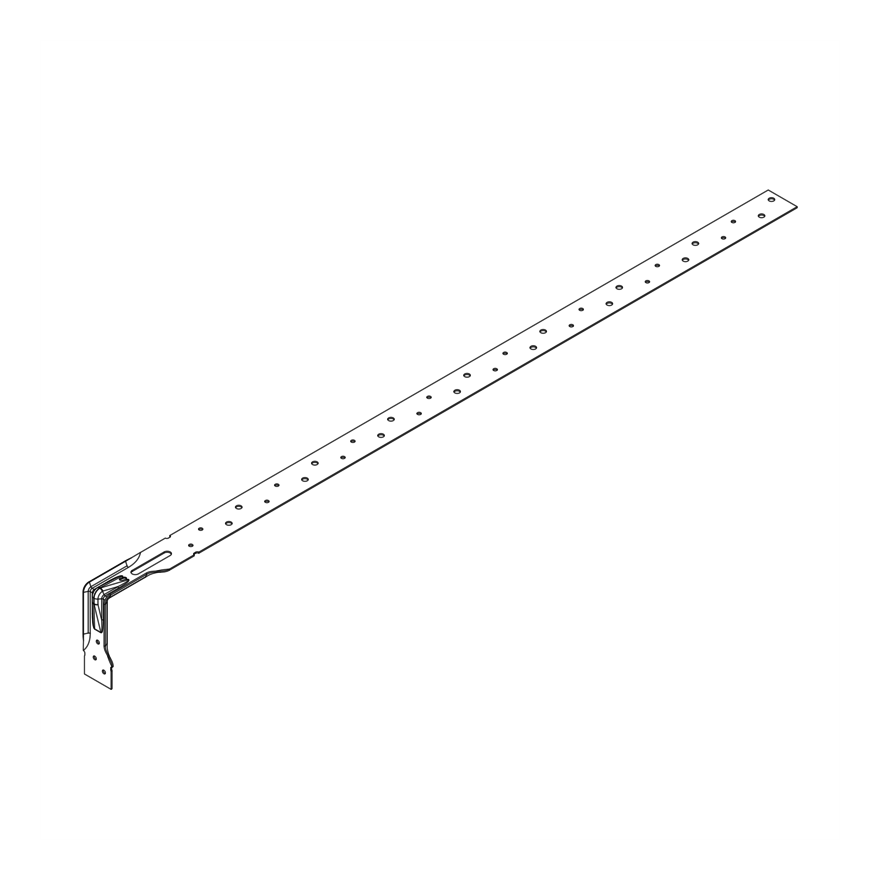

Horizontal strap installation

- Approved Document A of the Building Regulations requires lateral restraint to be provided at each floor at a maximum of 2 metre centres

- Restraint straps “perpendicular” to the floor joists are required to be held tight against the masonry and fixed across the first 3 joists

- Restraint straps “parallel” to the floor joists are required to be held tight to the masonry and be at least 1200mm long

- The characteristic tensile strength for horizontal restraint straps should not be less than 8 kN

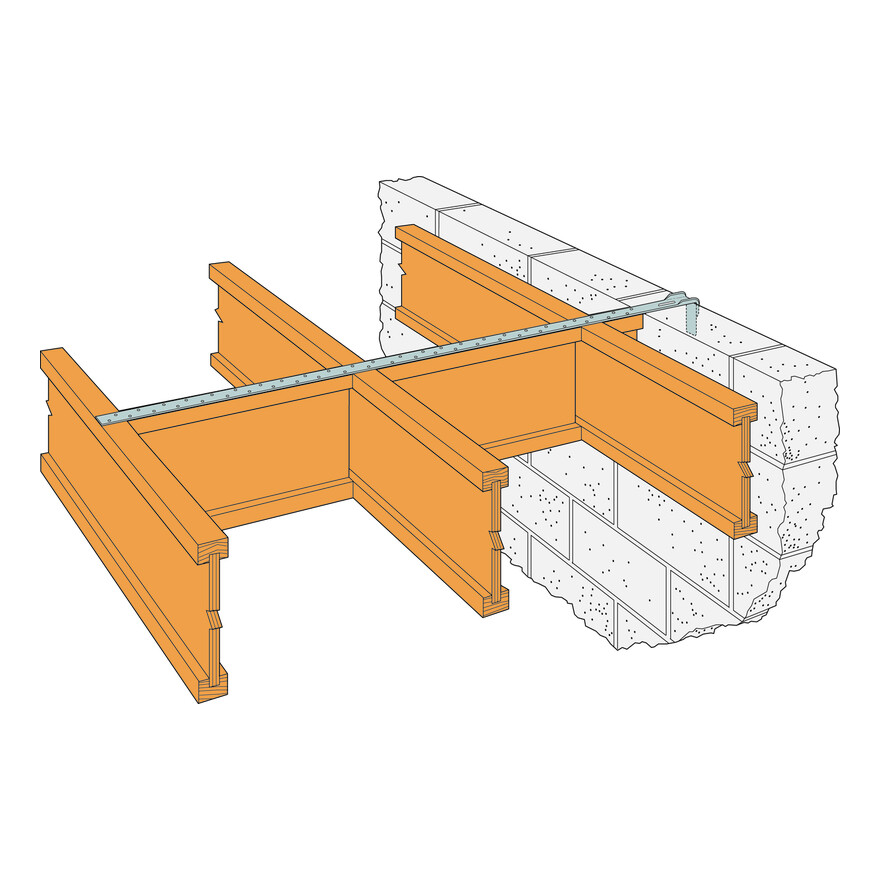

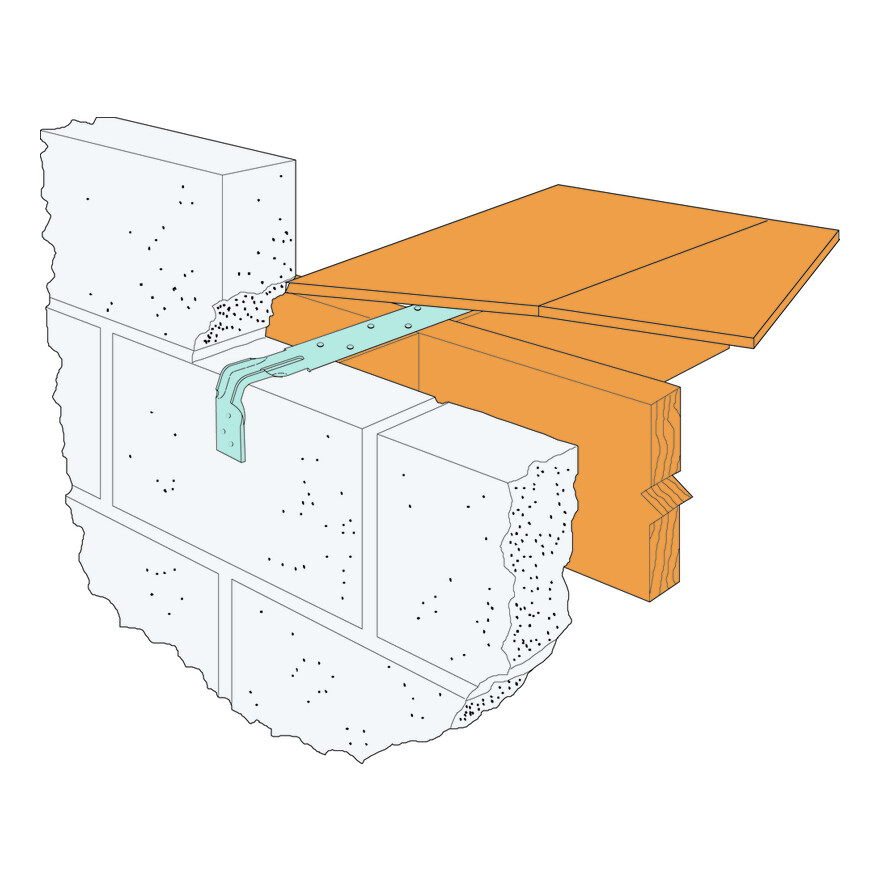

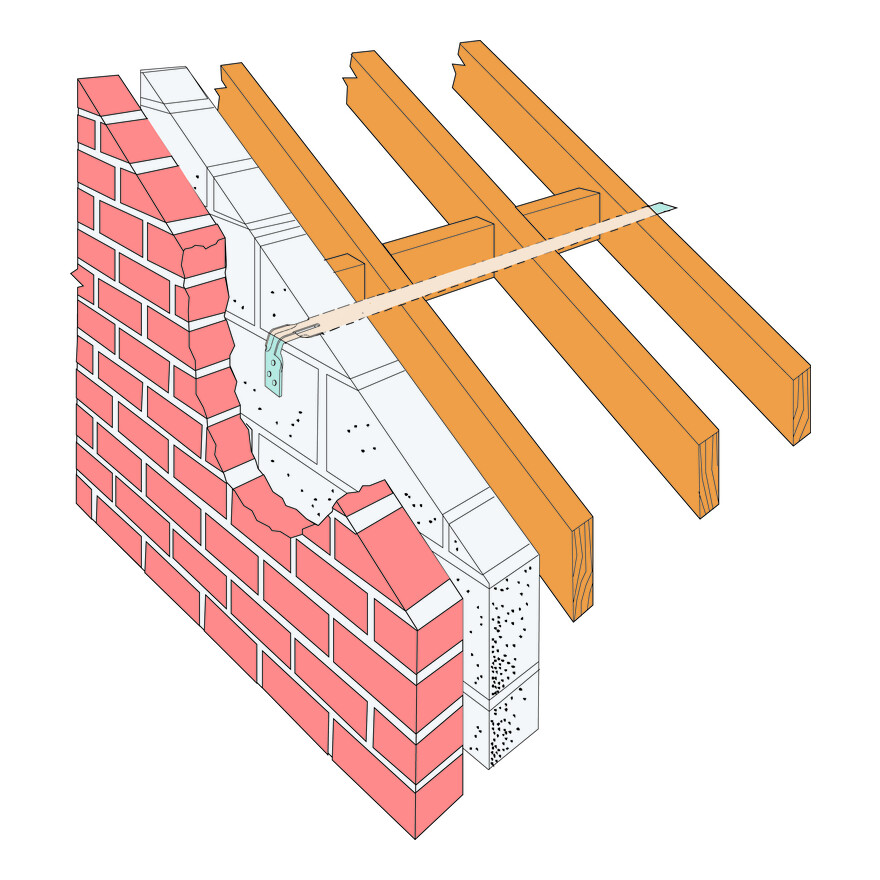

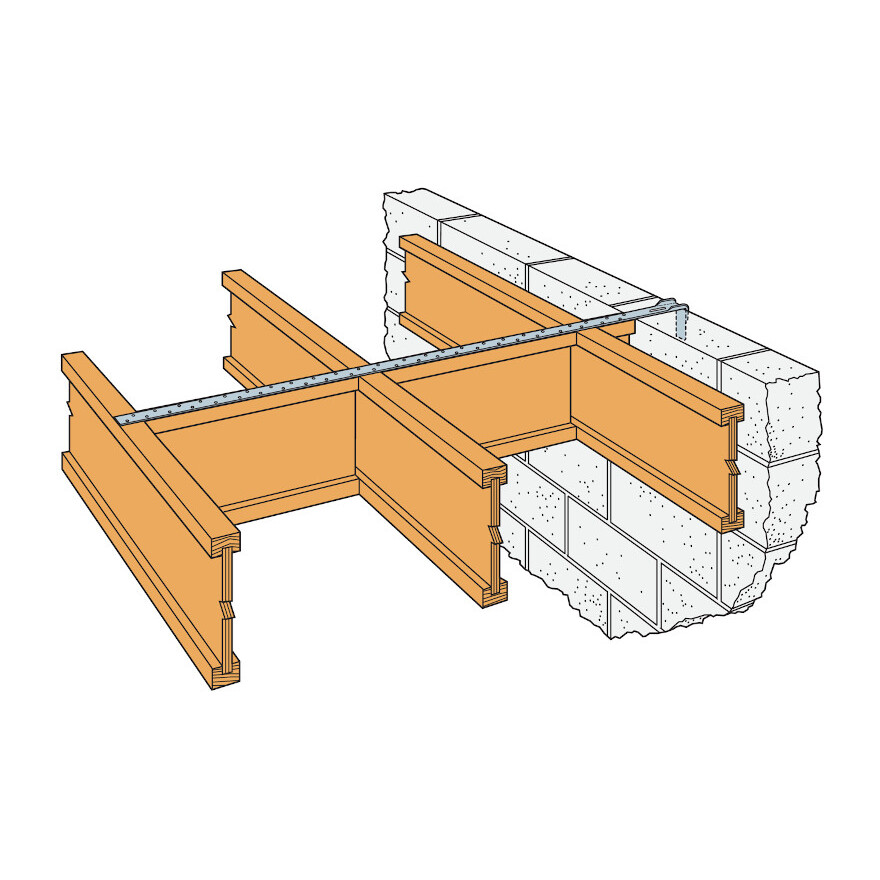

Installation - Floor

Horizontal lateral restraint straps should be spaced not more than 2m centres and attached to at least

3 timber members through the use of noggings and packing.

Attach to timber members using a minimum of 8 No 3.75 x 30mm square twist nails. The bend

length should be a minimum of 100mm and should be positioned at the centre of an uncut block or brick.

The downturn of strap is to be held tight against the cavity face of the inner leaf of blockwork.

Installation - Roof

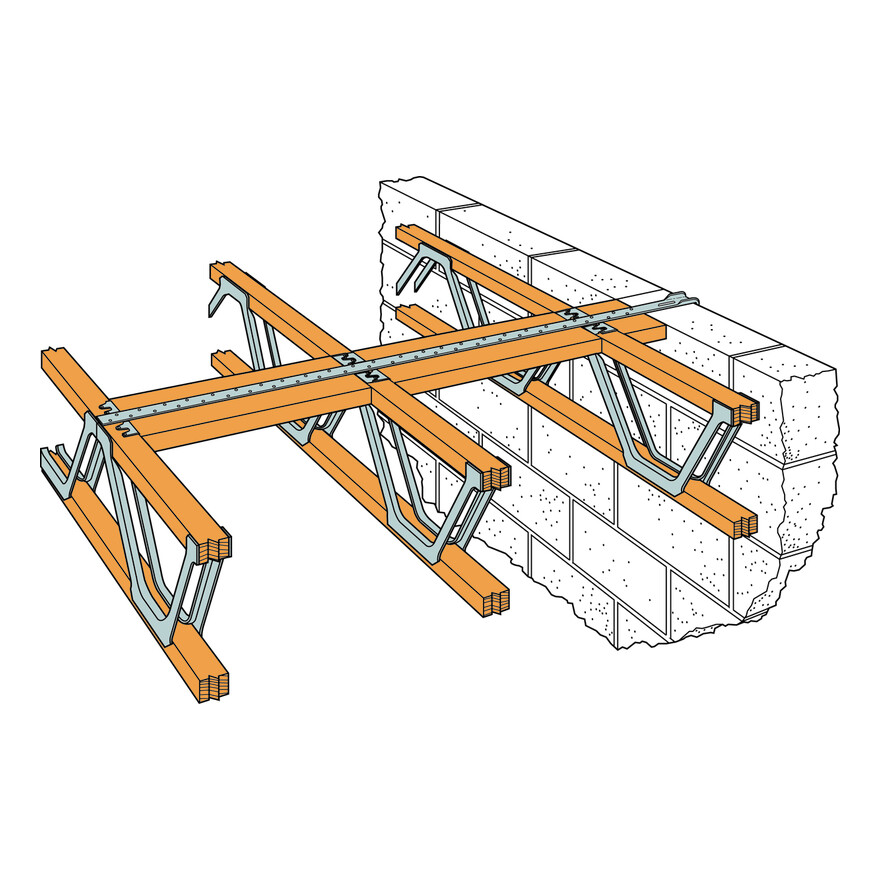

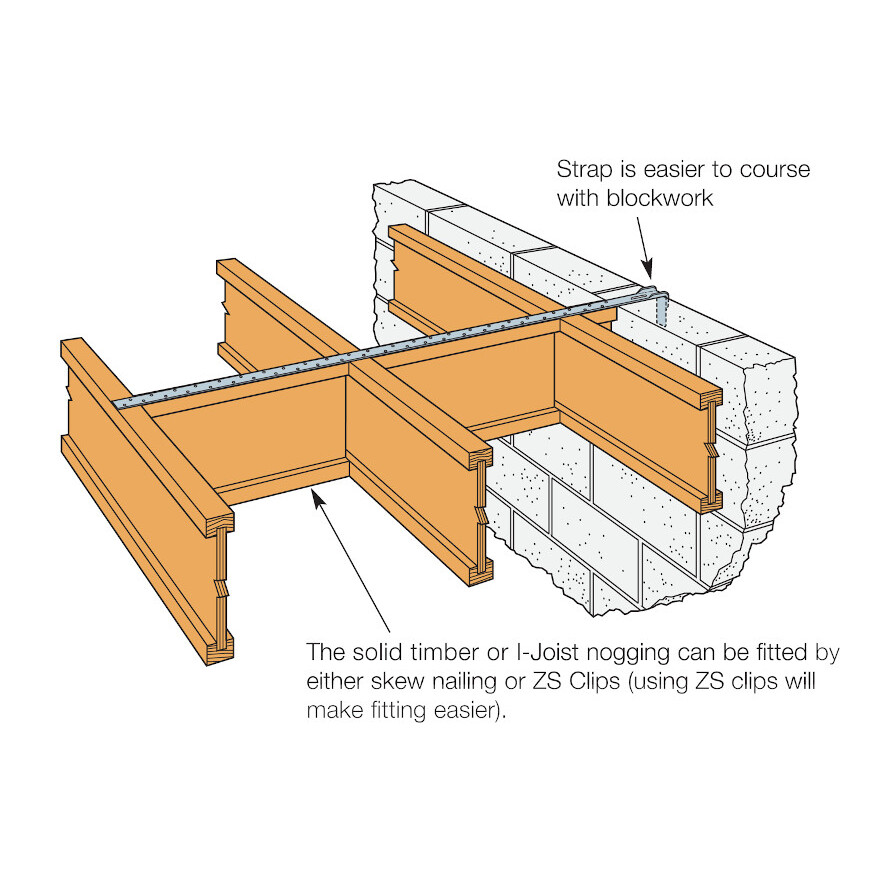

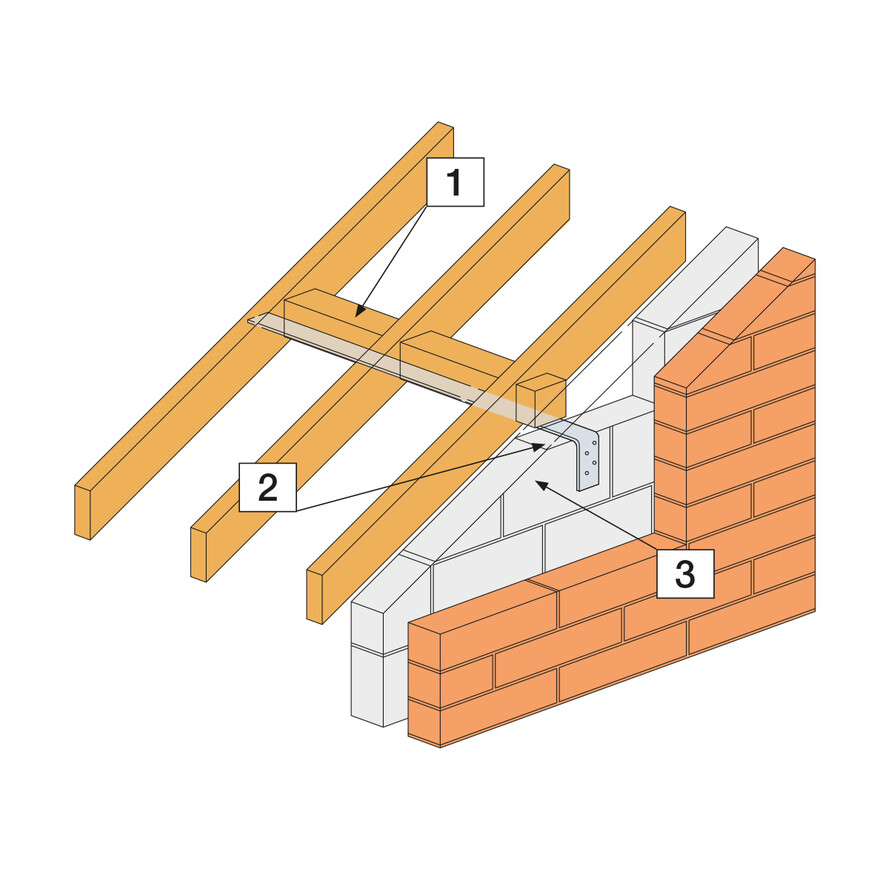

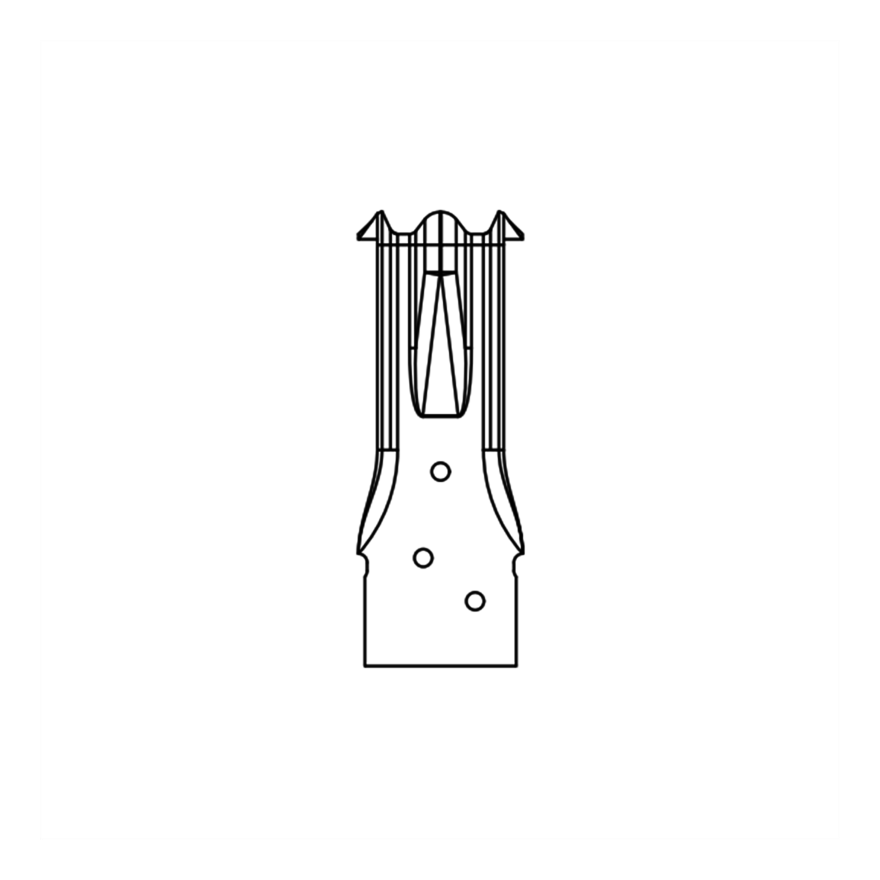

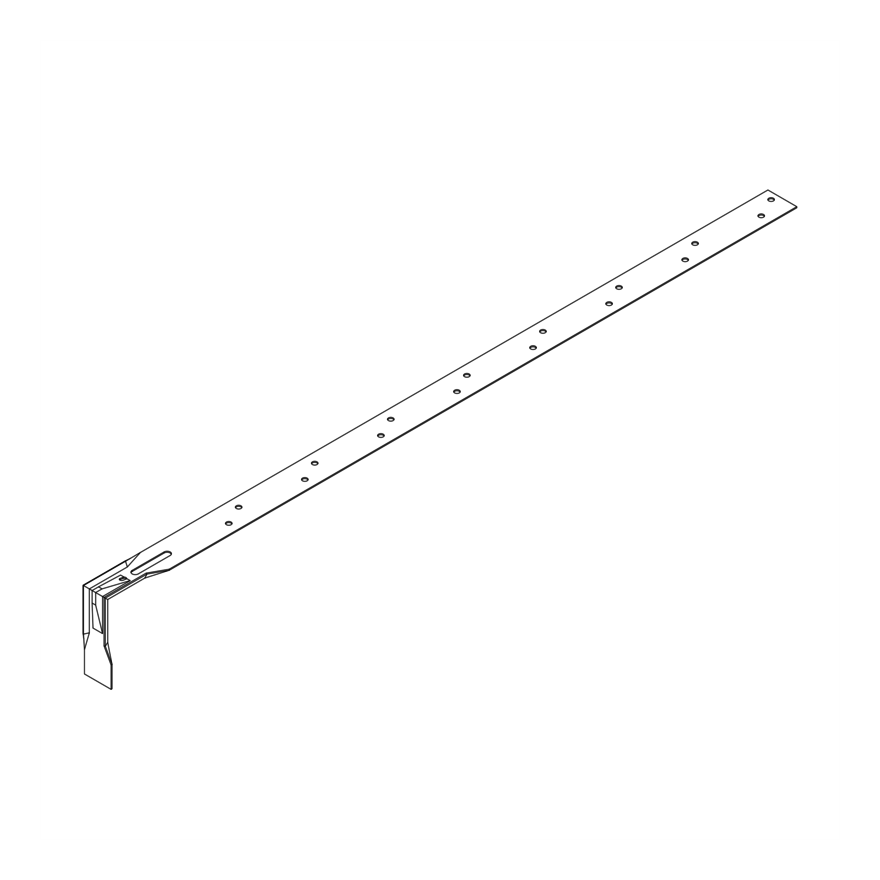

1. Fixing to Solid Noggings

- Straps to be installed at not more than 2m centres (or 1.25m where appropriate) along pitch of gable end.

- Ensure the position of the straps coincides with the block bed joint.

- Install HES or H strap to underside of solid noggings. Noggings to be fixed horizontally to avoid twisting of the restraint straps. (1)

- The downturn of strap is to be held tight against the cavity face of the inner leaf of blockwork (2), preferably located and bedded on a

substantial piece of blockwork, i.e. over the centre of a full block, with a single cut block over the strap. (3) - Fix straps to noggings/trusses with 8 No 3.75 x 30mm square twist nails, evenly distributed along the length of the strap.

(For NHBC warrantied buildings, in accordance with NHBC Standards 2017, section 7.2.8, 4 No 50mm (minimum) x 4mm steel screws

or 4 No 75mm x 4mm round wire nails, with one fixing into the third rafter, shall be used instead of the square twist nails). - Strap to be of sufficient length to be fixed to a minimum of three trusses.

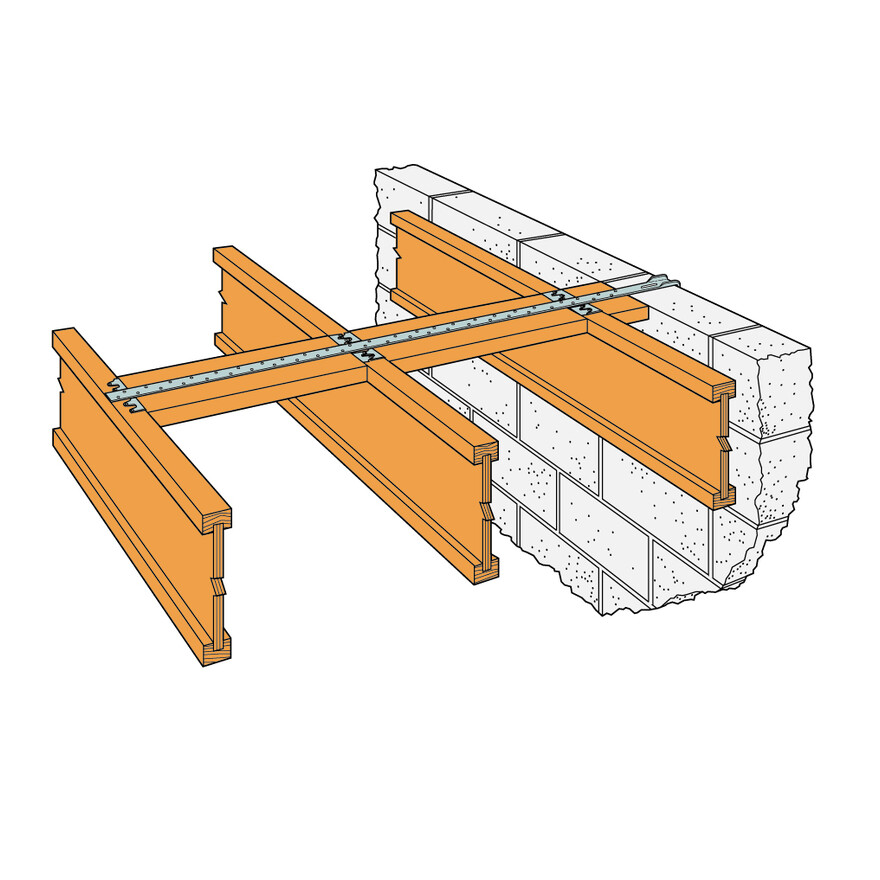

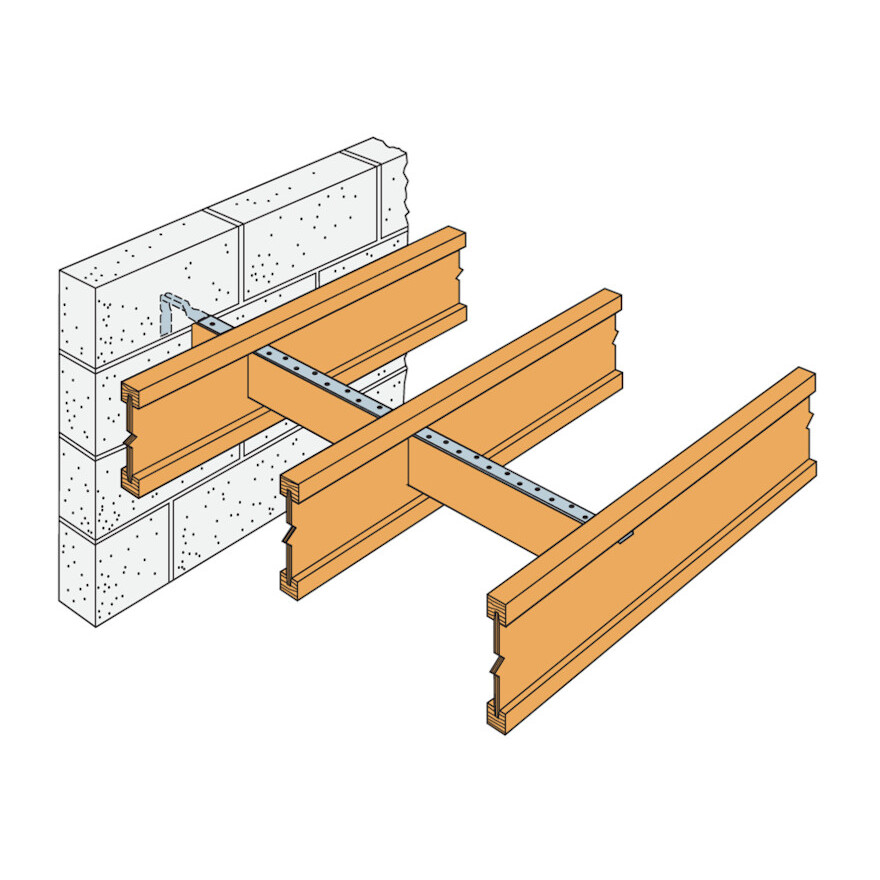

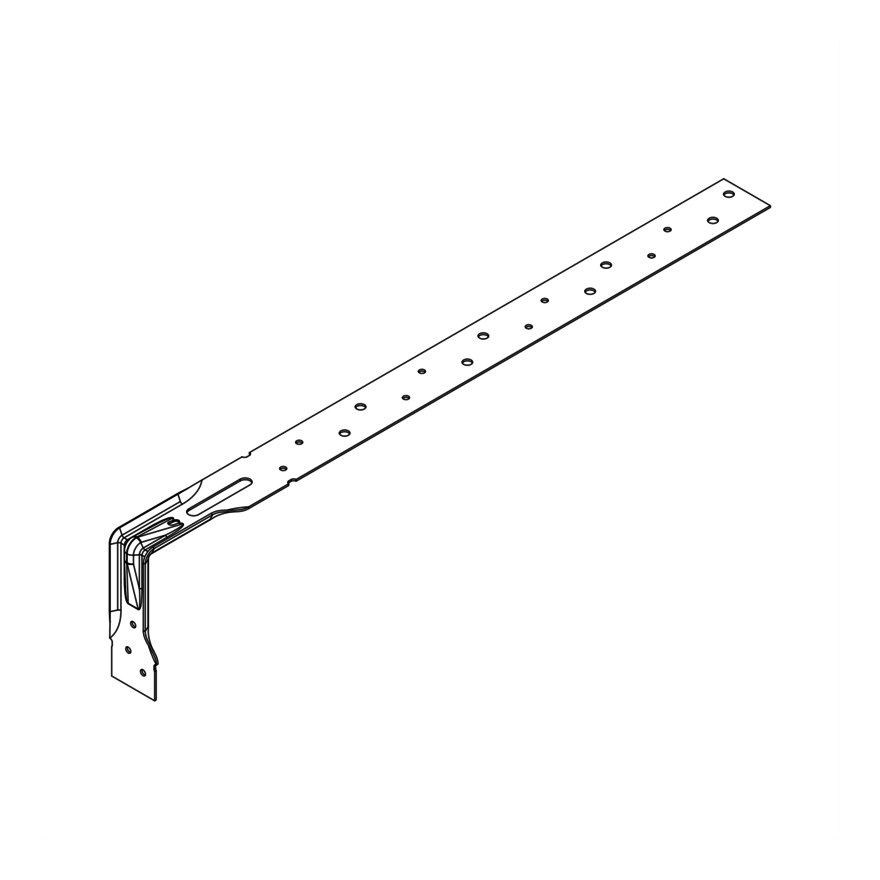

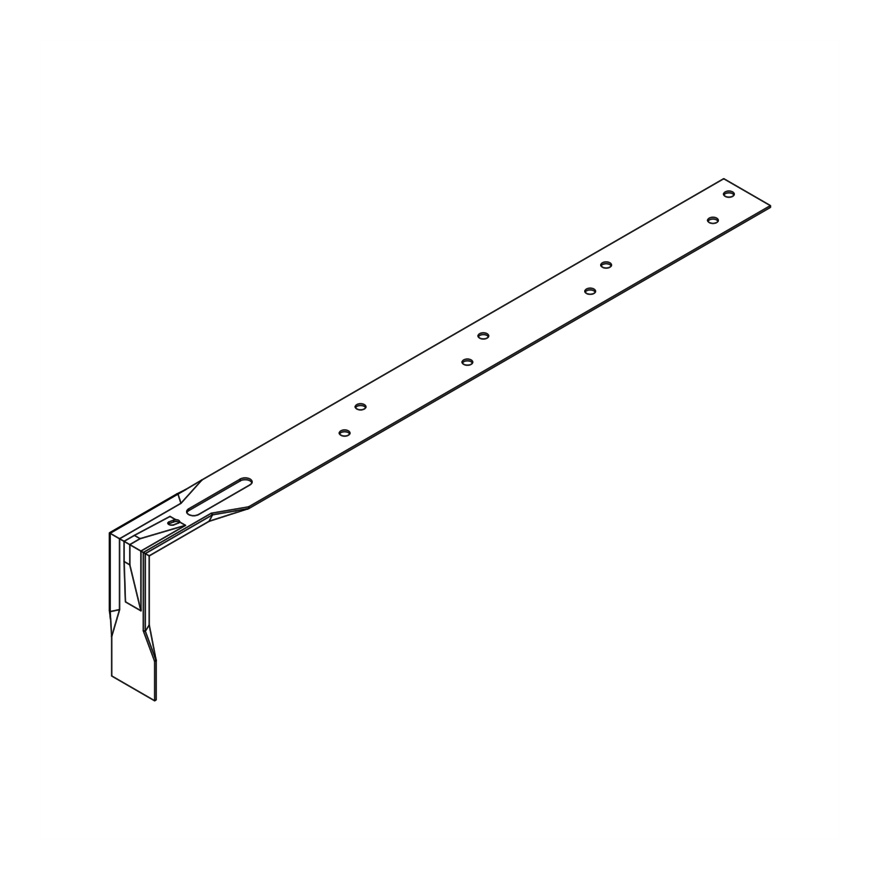

2. Fixing to Longitudinal Binder to Truss Web

- Straps to be installed at not more than 2m centres (or 1.25m where appropriate) along pitch of gable end

- Install HES or H strap on the 25 x 100mm longitudinal Web bracing (1)

- Where the position of the strap does not coincide with an existing longitudinal binder, then the strap may be fixed to an additional

25 x 100mm binder, as shown in the detail below. The binder is to be fixed over four trusses and nailed twice to each rafter with

3.35 x 65mm round wire nails. - The downturn of strap is to be held tight against the cavity face of the inner leaf of blockwork (2), preferably located on the full block.

Notch the blocks to accommodate the twist of the strap and ensure notch is fully mortared. - Fix straps to bracing with 8 No 3.75 x 30mm square twist nails, evenly distributed along the length of the strap (For NHBC warrantied

buildings, in accordance with NHBC standards 2017, section 7.2.8, 8 No 25mm x 4mm steel screws shall be used instead of the square

twist nails). - Strap to be of sufficient length to be fixed to a minimum of three trusses.

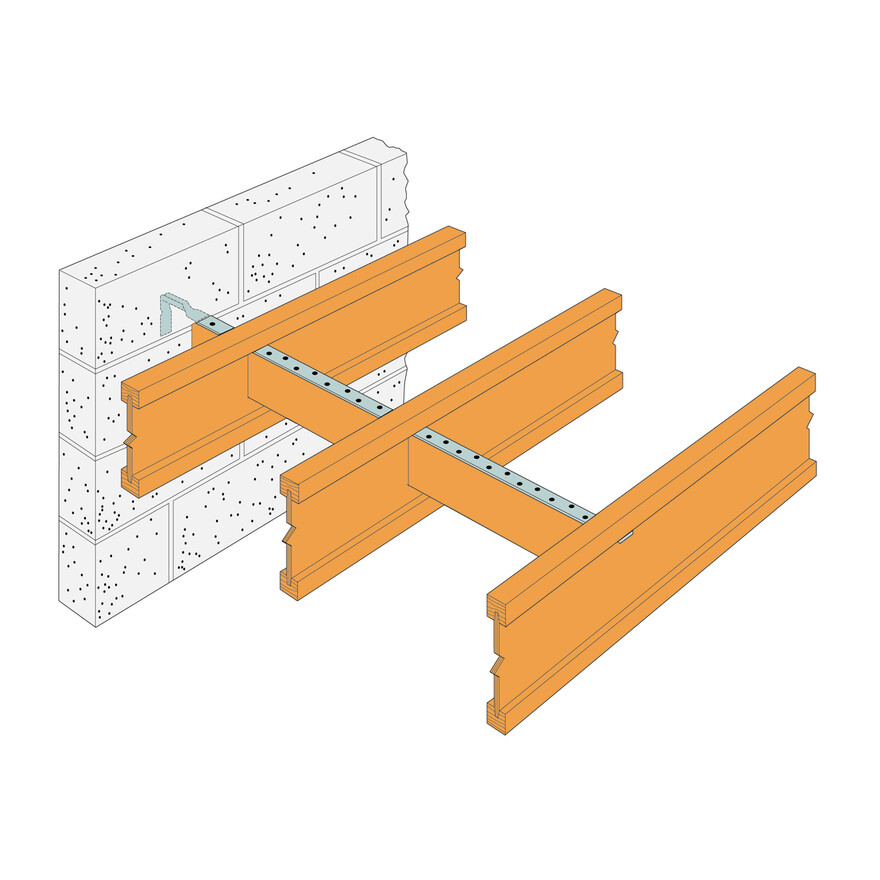

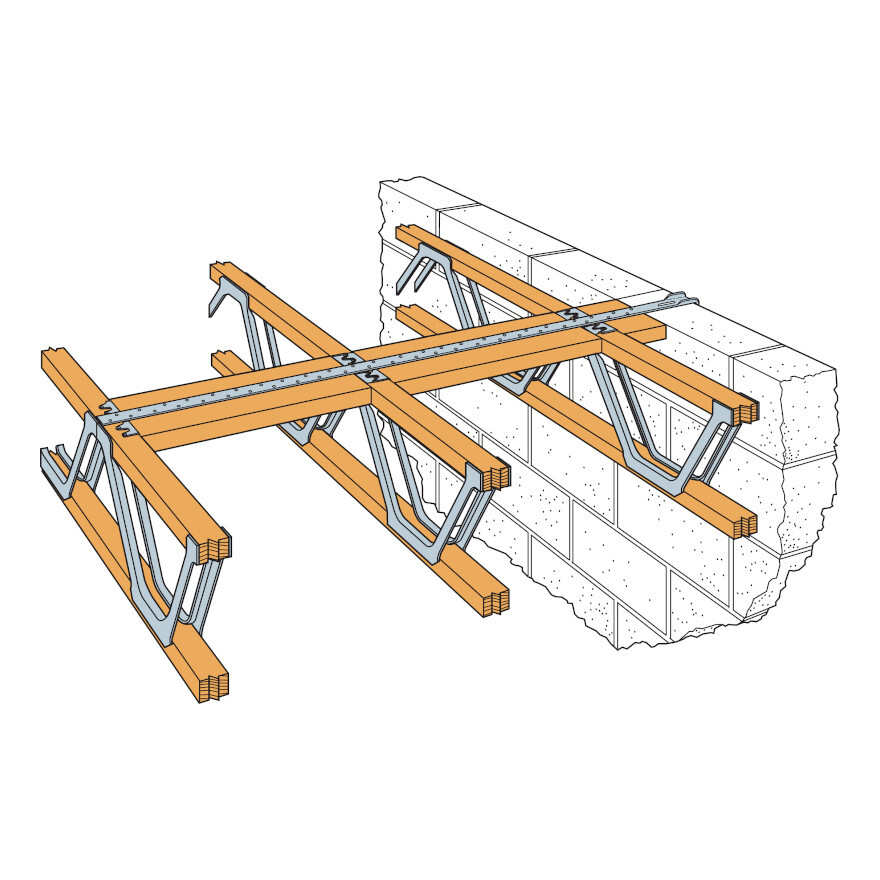

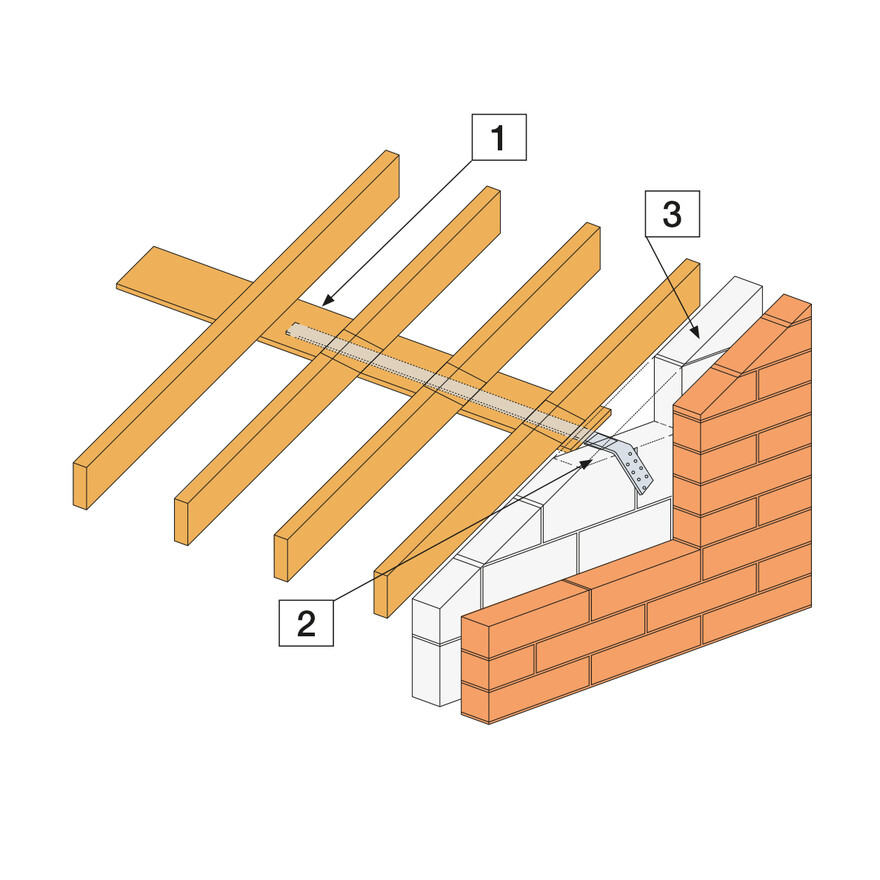

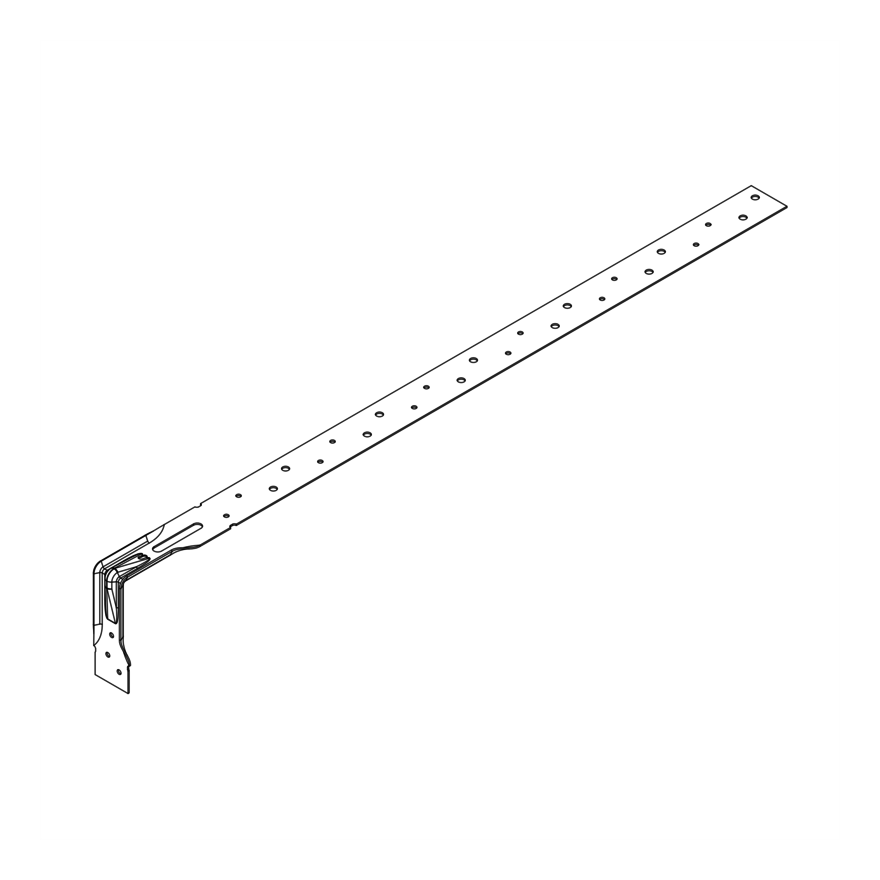

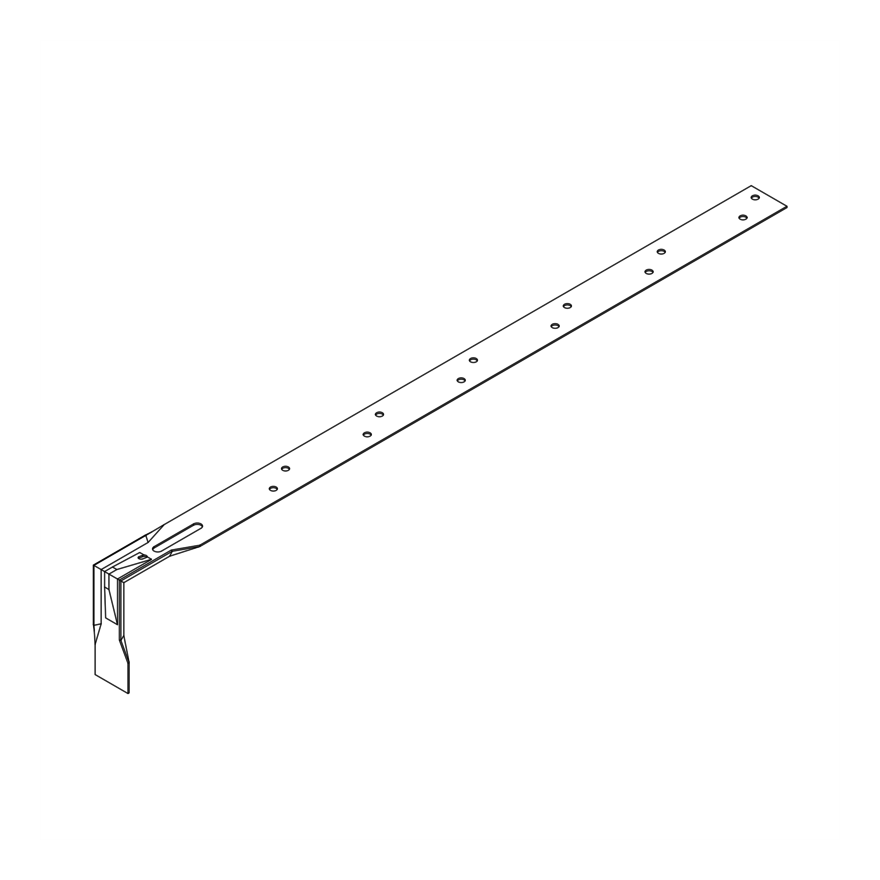

3. Fixing to Longitudinal Binder to Truss Rafter

- Straps to be installed at not more than 2m centres (or 1.25m where appropriate) along pitch of gable end.

- Install HES or H strap on the 25 x 100mm longitudinal Rafter bracing (1)

- Where the position of the strap does not coincide with an existing longitudinal binder, and block bed joint, then the strap can be fixed

to an additional 25 x 100mm binder. The binder is to be fixed over four trusses and nailed twice to each rafter with 3.35 x 65mm

round wire nails. - Ensure the position of the additional binder and strap coincide with the block bed joint

- The downturn of strap is to be held tight against the cavity face of the inner leaf of blockwork (2), preferably located and bedded on a

substantial piece of blockwork, i.e.over the centre of a full block, with a single cut block over the strap (3) (notch the block to

accommodate the twist of the strap and ensure notch is fully mortared). - Fix straps to bracing with 8 No 3.75 x 30mm square twist nails, evenly distributed along the length of the strap (For NHBC warrantied

buildings, in accordance with NHBC Standards 2017, section 7.2.8, 8 No 25mm x 4mm steel screws shall be used instead of the

square twist nails). - Strap to be of sufficient length to be fixed to a minimum of three trusses.

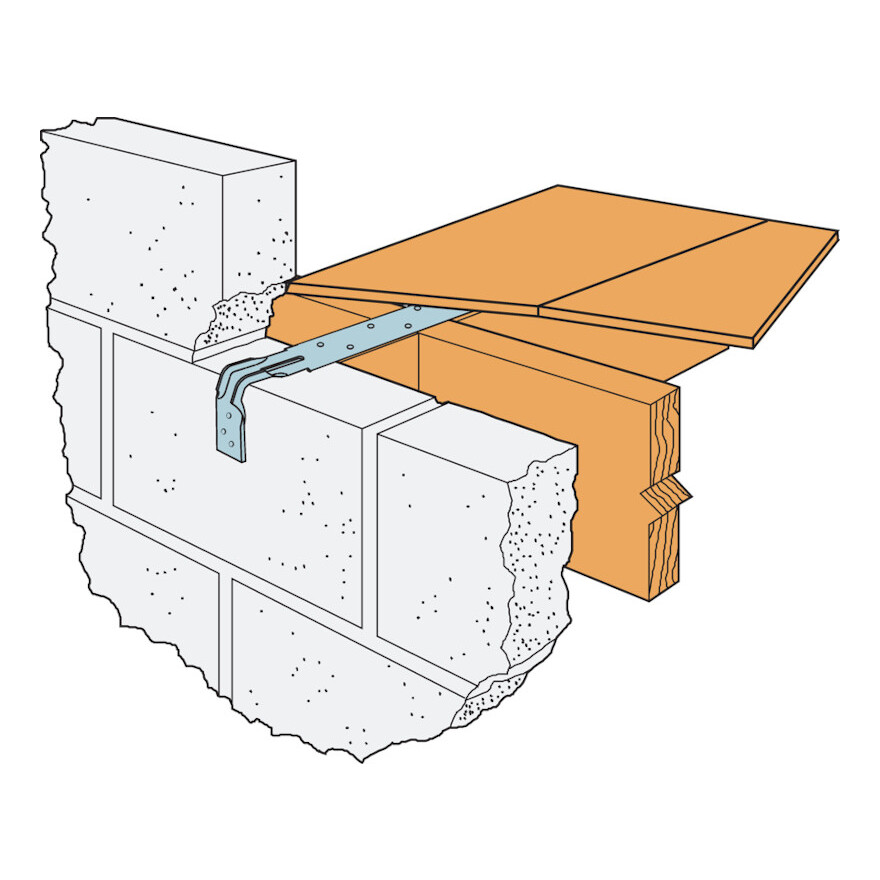

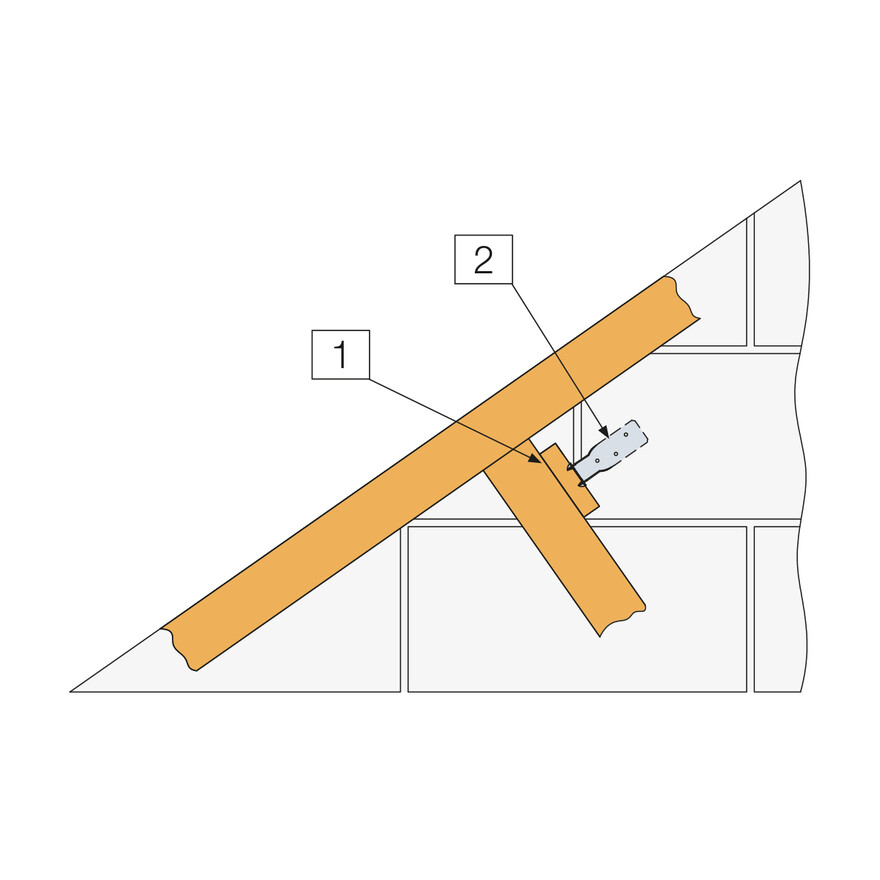

4/4a. Vertical Application

Fix LES or L strap to wall plate with 3 No 3.75 x 30mm square twist nails and to masonry with 5 No 5.5 x 50mm wood screws, plugged and screwed into masonry.

The lowest fixing should be located within 150mm of the bottom of the vertical strap.

Where L strap is fixed to truss, install with 3.75 x 30mm square twist nails, quantity depending on required uplift values.