High Performance Long Plug

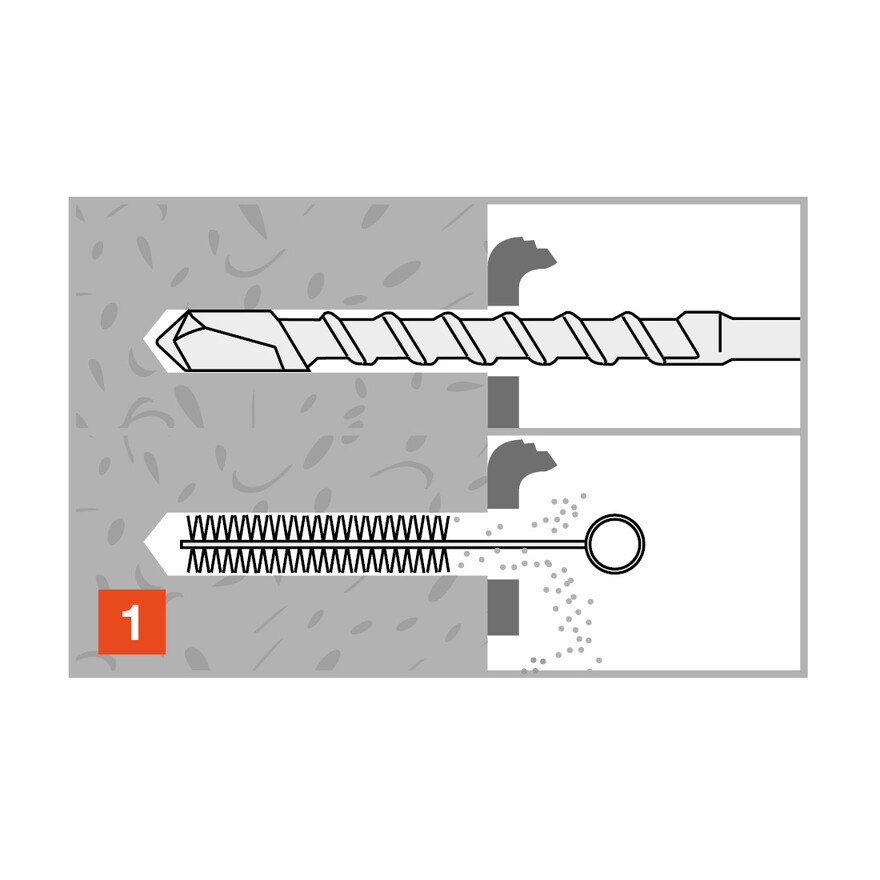

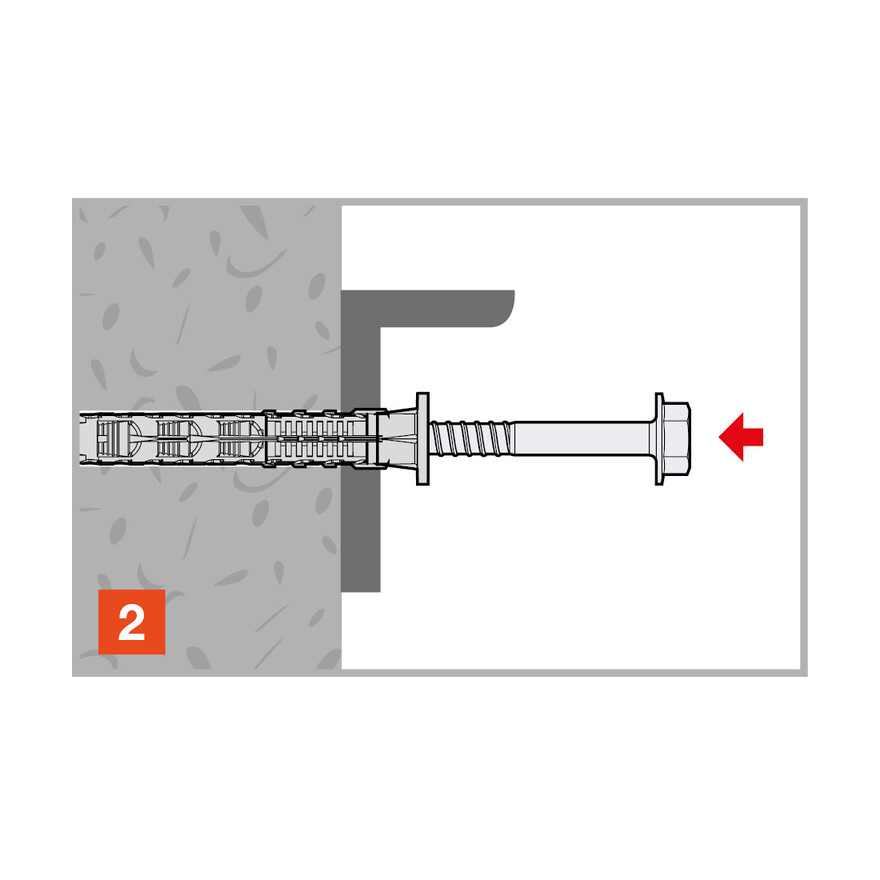

The X3 plugs in Ø8 and Ø10 mm versions in combination with countersunk / hexagon head screws are approved for multiple fixings in concrete and masonry.

Product Details

Features

Material

Plug: nylon

Screw: white zinc plated steel

Benefits

- Extraordinary performance on all base materials.

- Up to 3 embedment depths

- Extreme versatility and significant reduction in installation time.

- Increased expansion

- Designed for facades and heavy carpentry.

Application

Applications

- Ventilated facades

- Steel carpentry

- Wood carpentry

Suitable for

Non-cracked concrete

Solid brick

Honeycomb brick

- Cell like clay brick

- Lightweight honeycomb brick

- Hollow dense aggregate block

- Hollow light aggregate block

- Aerated concrete

- Solid stone

Technical Data

Autres

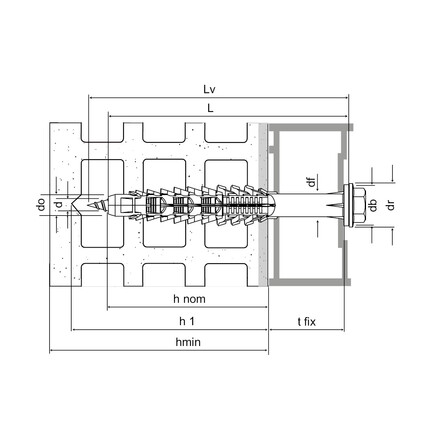

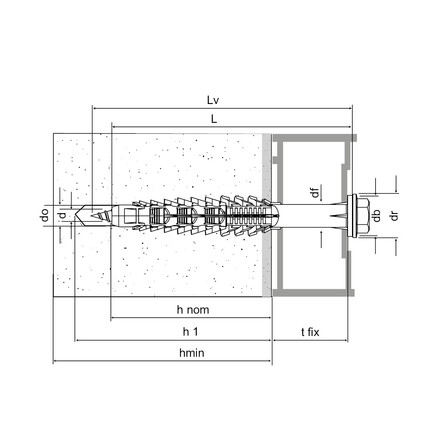

Product Dimension - Countersunk PZ Screw

| References | Product Reference | DB nr. | NOBB nr. | Plug [ØxL] [mm] | Screw [ØxL] [mm] | Reduced fixture thickness [tfix] [mm] | Standard fixture thickness [tfix] [mm] | Increased* fixture thickness [tfix] [mm] | Bit | Qty per box | Qty per outer box |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 64601B0810000 | X3 | - | - | 8x100 | 6x108 | 60 | 50 | - | PZ3 | 50 | 500 |

(1) Only for aerated concrete

* Not covered by CE certification

Design capacities - single anchor - no edge distances

1. The design loads loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

*Not covered by ETA-11/0080

Recommended capacities - single anchor - no edge distances

1. The recommended loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s) and with a partial safety factor for actions of γF=1.4. The loading figures

are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10 mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per

ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).