Kneewall Connector

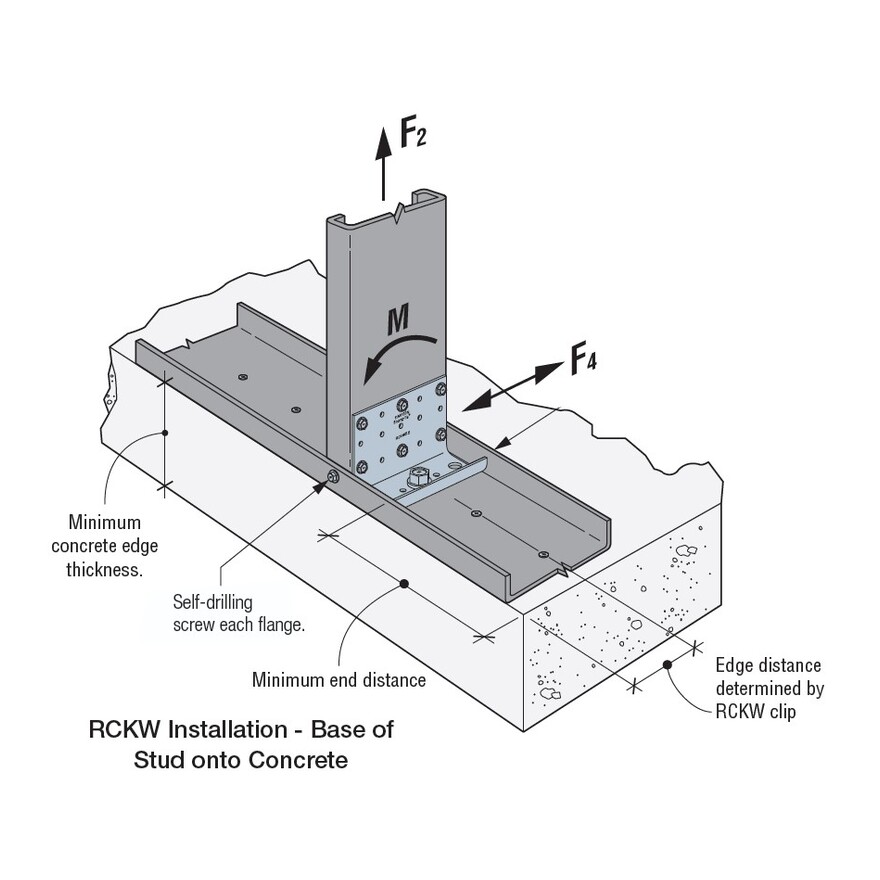

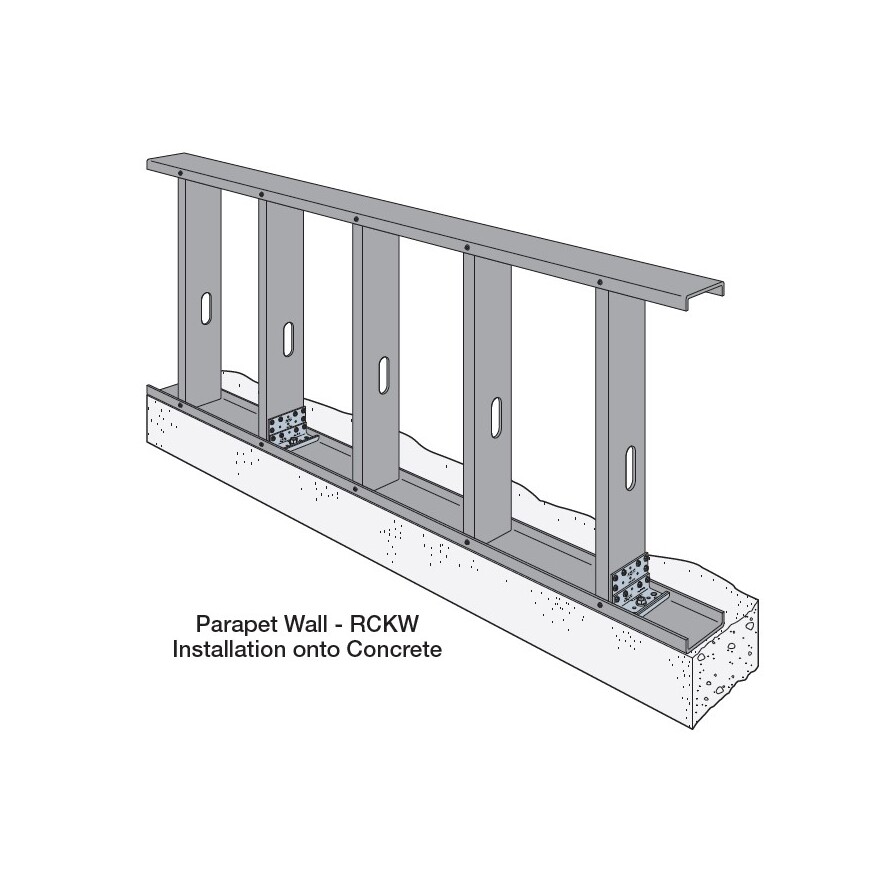

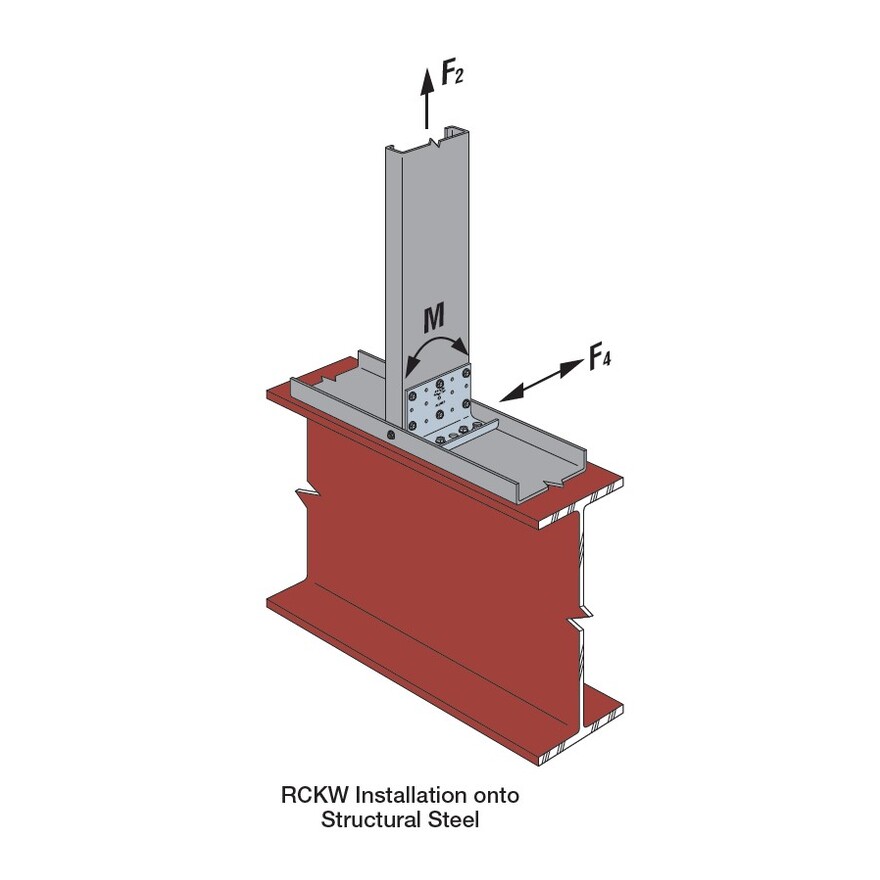

The Simpson Strong-Tie® RCKW is a heavy duty rigid connector that has been developed to resist an overturning moment at the base of exterior kneewalls and parapets as well as interior partial height walls or overhead ribbon window conditions.

Product Details

Features

Features

The RCKW is a 1 or 2 part connector designed to resist an over-turning moment at the base of exterior knee-walls and parapets as well as interior partial height walls.

These connectors offer a unique large and small anchorage hole pattern that permits anchorage into both hot rolled steel and concrete.

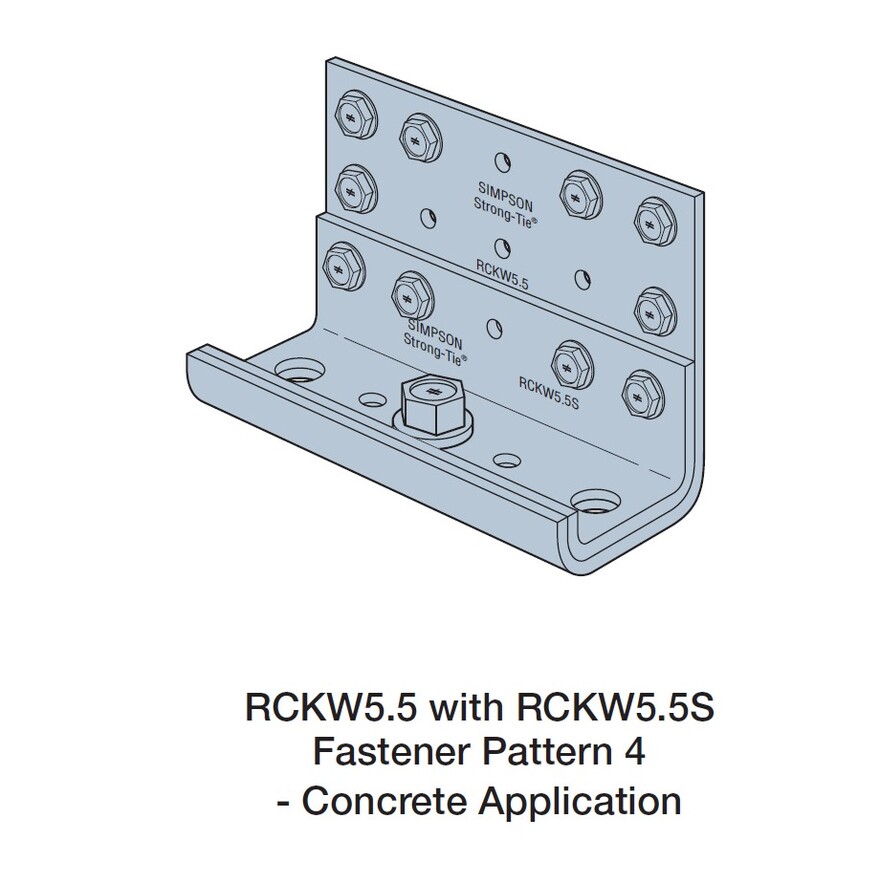

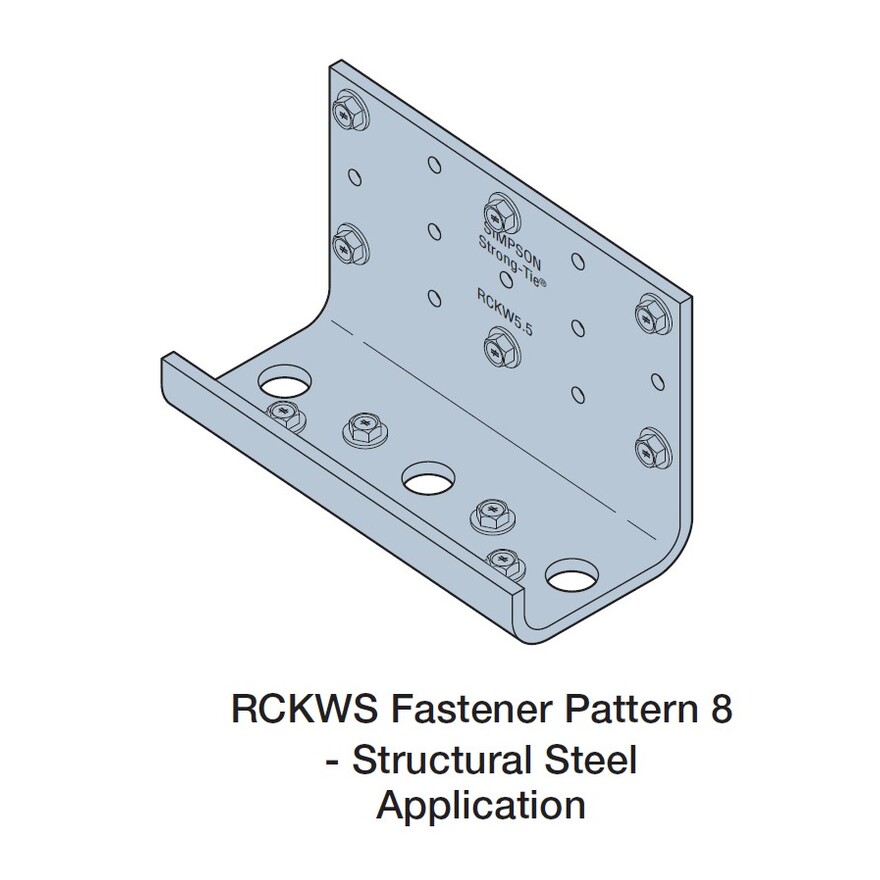

If more rigidity is required, a stiffener (the RCKWS) can be added to nest into the RCKW clip; the screw and anchor holes line up making installation simple, with no need for pre drilling. The RCKW and the RCKWS are sold separately.

Key Features include:

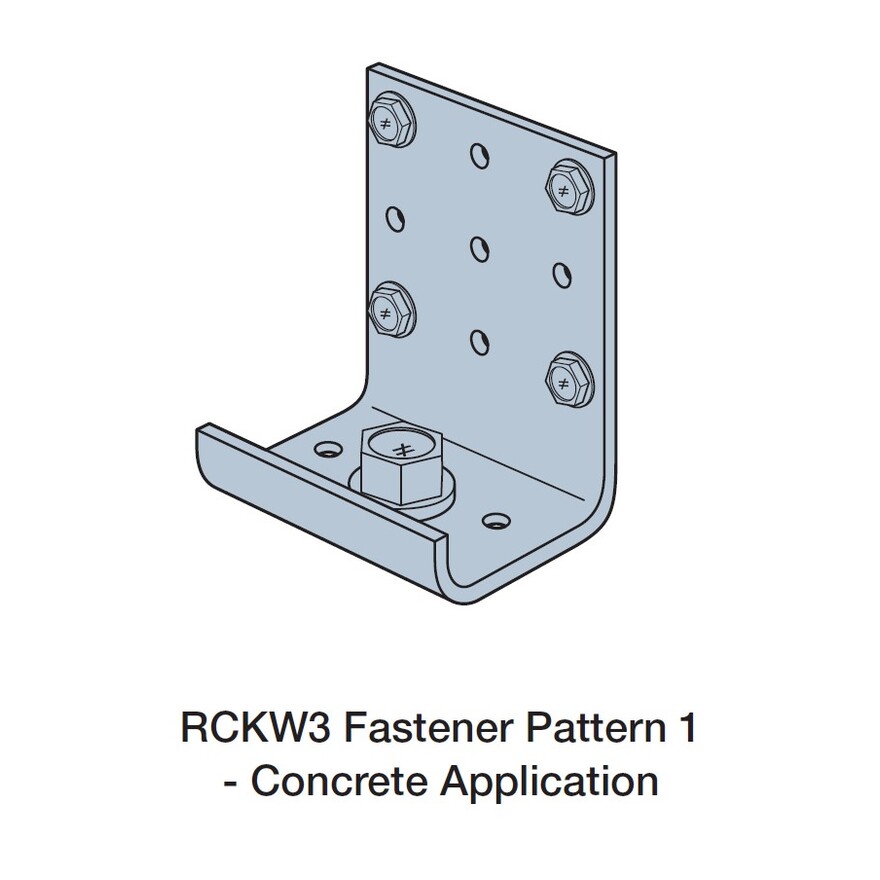

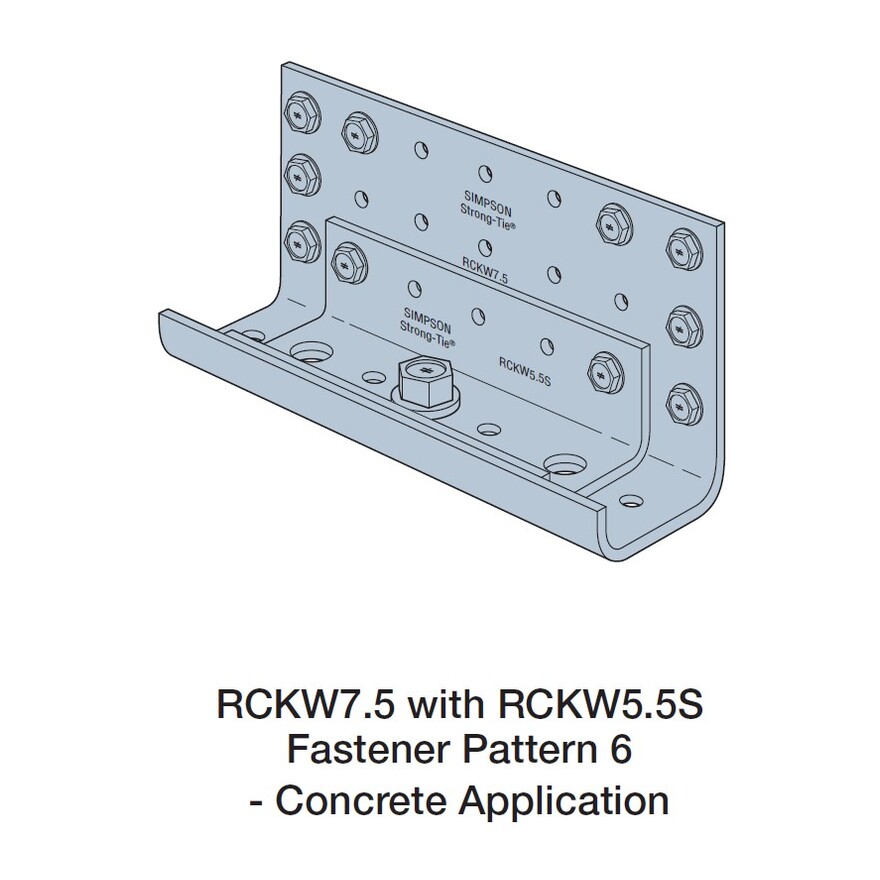

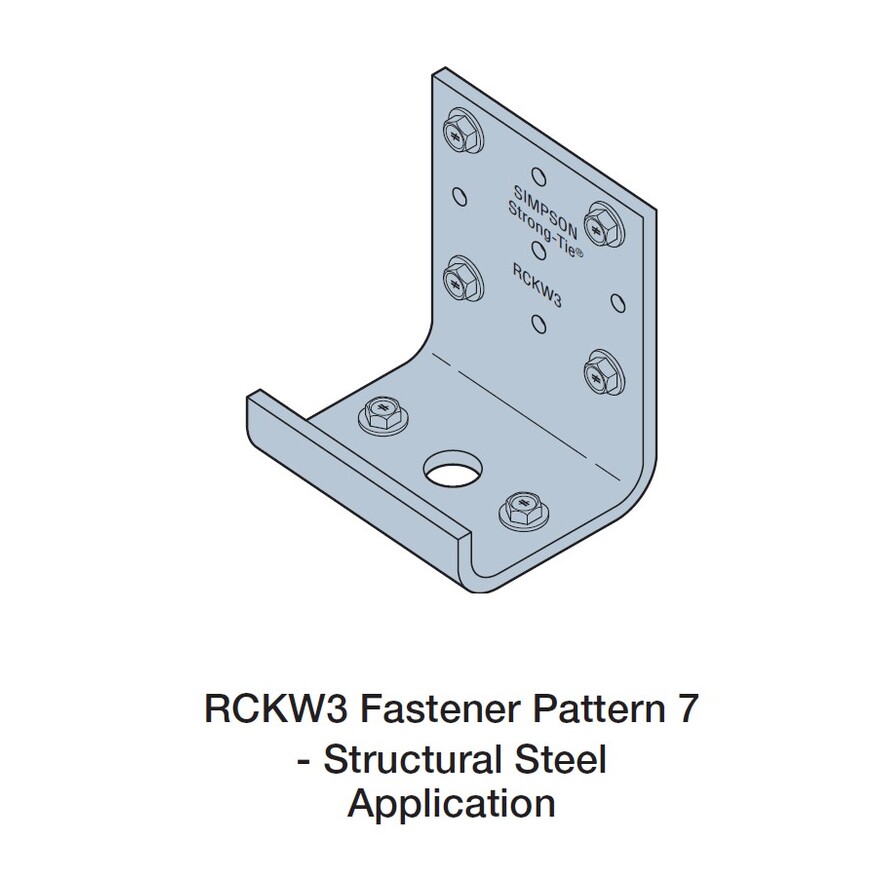

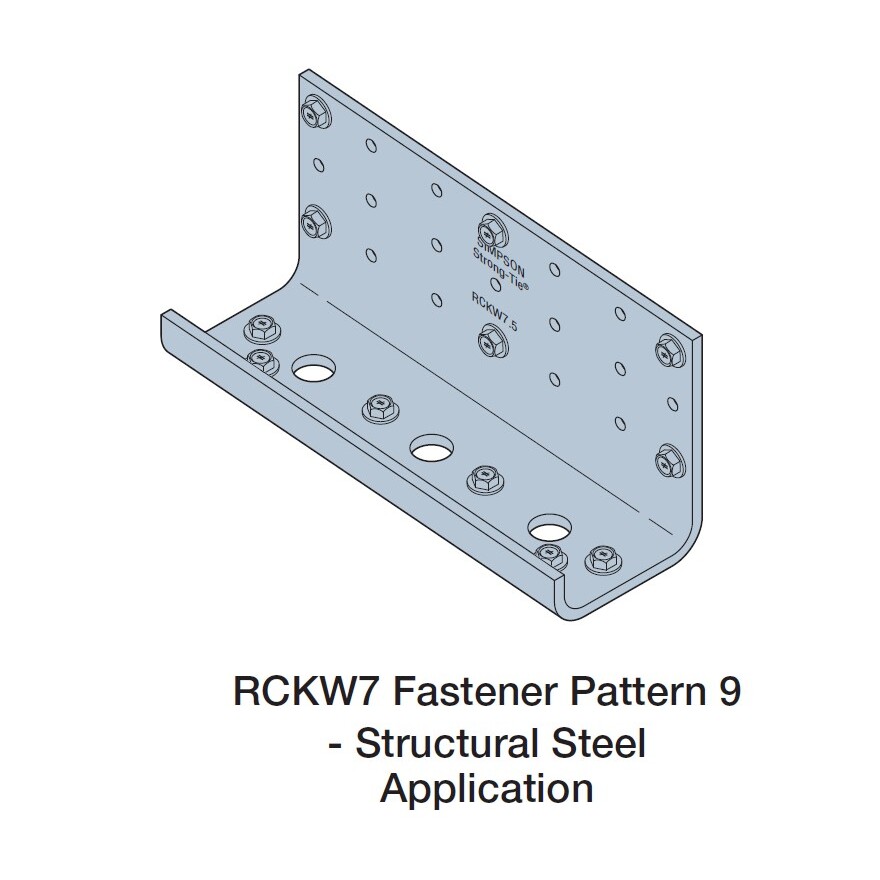

- Anchorage legs incorporate stifened flanges, improving over-turning moment resistance

- Large diameter anchor holes accommodate 12 mm diamter fixings (LMAS stud with AT-HP Resin)

- Additional smaller diameter anchor holes allow for the attachment to hot rolled steel with X1224D540 self-drilling screws.

Material

Galvanised Mild Steel: 275 g/m2

Technical Data

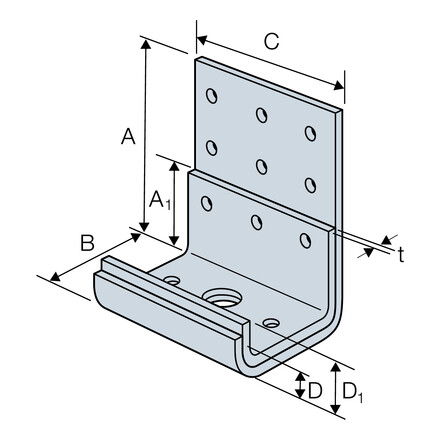

Product Dimensions

Performance Values - 1.2mm LGS (Concrete)

| References | Fasteners | Minimum Framing Member Depth [mm] | Screw Installation Pattern | Assemby Rotational Stiffness β [Nm/Rad] | Connector Rotational Stiffness βc [Nm/Rad] | Safe Working Loads [kN] | Characteristic Loads [kN] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange A Stud | Flange B Concrete | Moment MR,SWL [Nm] | Anchor Tension at MR Capacity | Tension R2,SWL | Anchor Tension at R2 Capacity | Shear R4,SWL | Moment MR,K [Nm] | Anchor Tension at MR Capacity | Tension R2,K | Anchor Tension at R2 Capacity | Shear R4,K | ||||||||

| Qty (X1214D325) | Qty (M12 Anchor) | Concrete C20/25 | Concrete C30/35 | Concrete C20/25 | Concrete C30/35 | Concrete C20/25 | Concrete C30/35 | Concrete C20/25 | |||||||||||

| Concrete C30/35 | |||||||||||||||||||

| RCKW3+RCKW3S | 9 | 1 | 90 | 2 | 18530 | 19772 | 476 | 17.5 | 15.4 | 11.5 | 19.6 | 16.7 | 3.5 | 648 | 21.8 | 20 | 15.7 | 21.7 | 4.8 |

| RCKW5.5+RCKW5.5S | 10 | 1 | 150 | 4 | 50843 | 55363 | 954 | 15.9 | 15.2 | 11.4 | 15.3 | 14.6 | 4.6 | 1299 | 21 | 20.3 | 15.5 | 19.5 | 6.3 |

| RCKW7.5+RCKW5.5S | 10 | 1 | 200 | 6 | 66774 | 70390 | 1233 | 14.3 | 13.9 | 10 | 12.6 | 12.3 | 5.3 | 1678 | 19.1 | 18.7 | 14.8 | 18.1 | 7.3 |

Performance Values - 1.6mm LGS (Concrete)

| References | Fasteners | Minimum Framing Member Depth [mm] | Screw Installation Pattern | Assembly Rotational Stiffness β [Nm/Rad] | Connector Rotational Stiffness βc [Nm/Rad] | Safe Working Loads [kN] | Characteristic Loads [kN] | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange A Stud | Flange B Concrete | Moment MR,SWL [Nm] | Anchor Tension at MR Capacity | Tension R2,SWL | Anchor Tension R2 Capacity | Shear R4,SWL | Moment MR,K [Nm] | Anchor Tension at MR Capacity | Tension R2,K | Anchor Tension at R2 Capacity | Shear R4,K | |||||||||

| Qty (X1214D325) | Qty (M12 Anchor) | Concrete C20/25 | Concrete C30/35 | Concrete C20/25 | Concrete C30/35 | Conrete C20/25 | Concrete C30/35 | Concrete C20/25 | Concrete C30/35 | |||||||||||

| RCKW3+RCKW3S | 9 | 1 | 90 | 2 | 18530 | 19772 | 583 | 29.8 | 20.4 | 15.3 | 27.3 | 25.9 | 5 | 908 | 39.6 | 31.2 | 22.5 | 40.2 | 35.5 | 7.3 |

| RCKW5.5+RCKW5.5S | 10 | 1 | 150 | 4 | 52764 | 56718 | 1308 | 23.8 | 21.9 | 16.9 | 25.2 | 23.1 | 6.2 | 1917 | 33.7 | 31.5 | 24.9 | 35.8 | 33.4 | 9.1 |

| RCKW7.5+RCKW5.5S | 10 | 1 | 200 | 6 | 77847 | 81349 | 1587 | 19 | 18.3 | 11.7 | 14.9 | 14.5 | 7.5 | 2336 | 27.6 | 26.7 | 25.3 | 33.8 | 32.4 | 11.1 |

Performance Values - 1.6mm LGS (Structural Steel)

Table Notes:

1. Tabulated values are based on framing members with track and stud of the same thickness and (1) Ø5.5mm Framing Screw into each stud flange unless otherwise noted.

2. Tabulated moment values correspond to connector strength without consideration of serviceability. designer must check out-of-plane deflections using tabulated Rotational Stiffness.

3. Tabulated Assembly Rotational Stiffness is applicable for walls at 950mm tall with corresponding framing member depth and thickness.

4. Tabulated Connector Rotational Stiffness may be used for any wall heights; the designer must consider member deflection due to bending in the stud member.

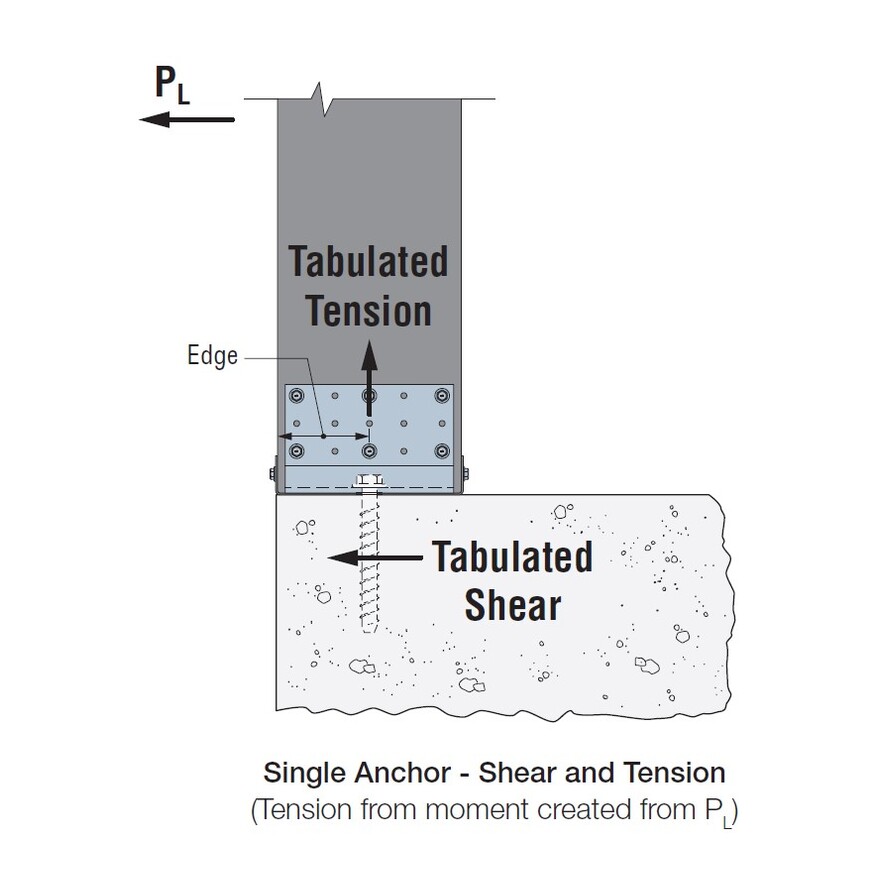

5. Anchor tension (T) is the force in the anchor, at the tabulated momement (M), or tension (F2) values.

6. The designer is responsible for anchor design / specification

7. The designer is responsible for structural steel design.

8. Anchor tension values may be interpolated

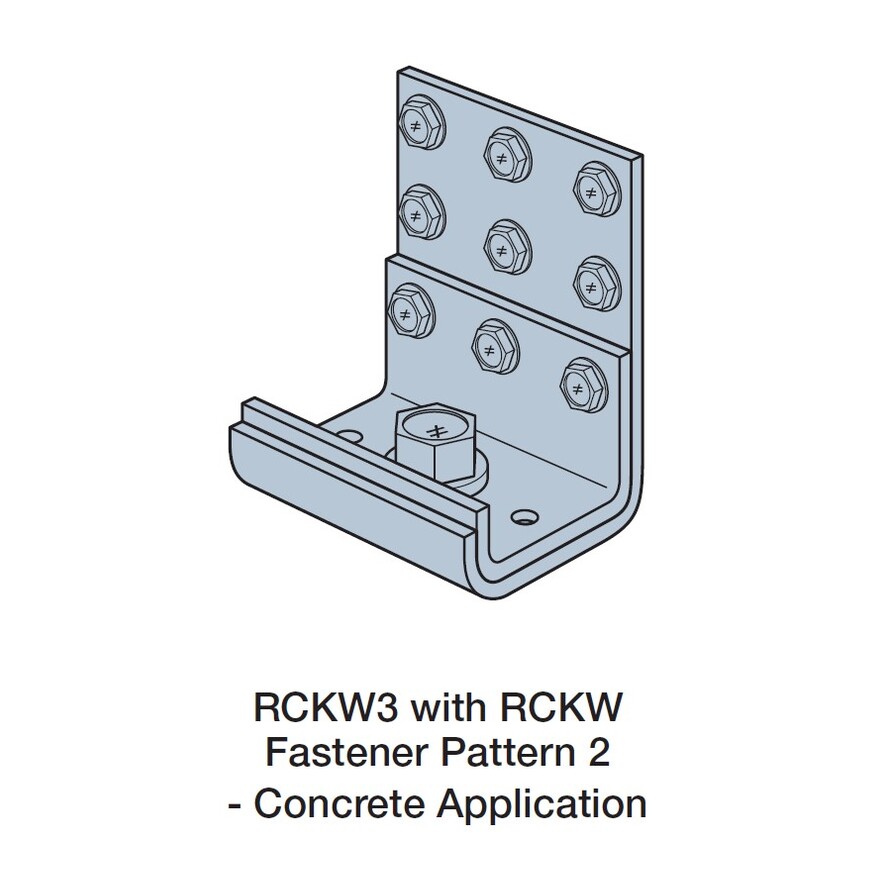

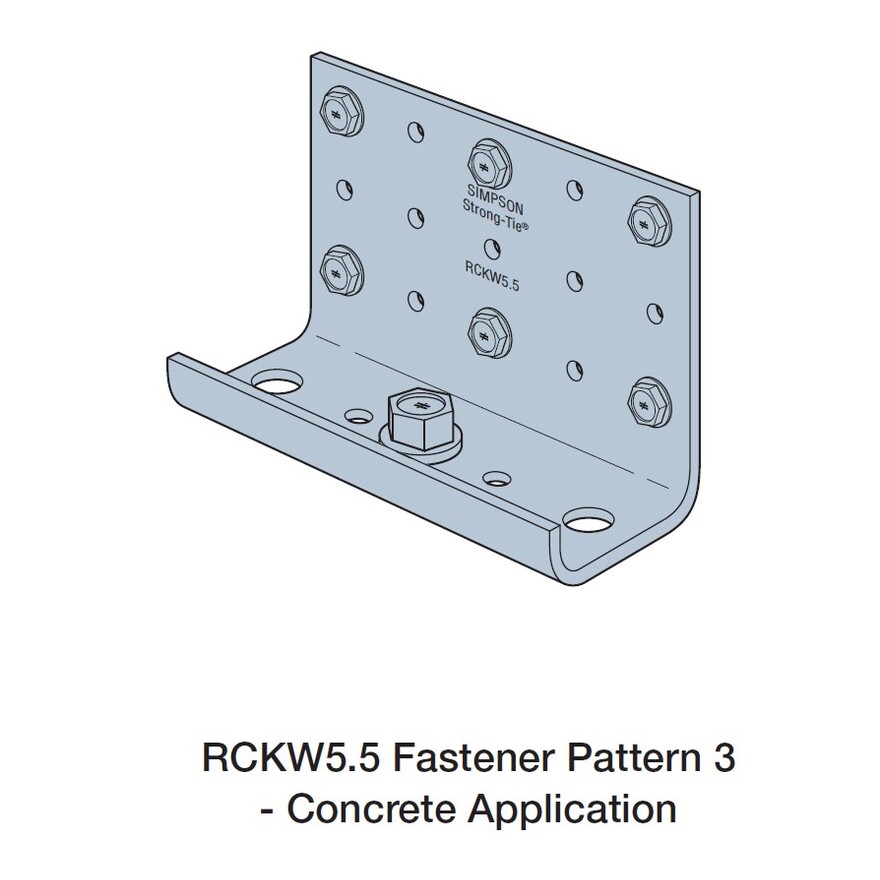

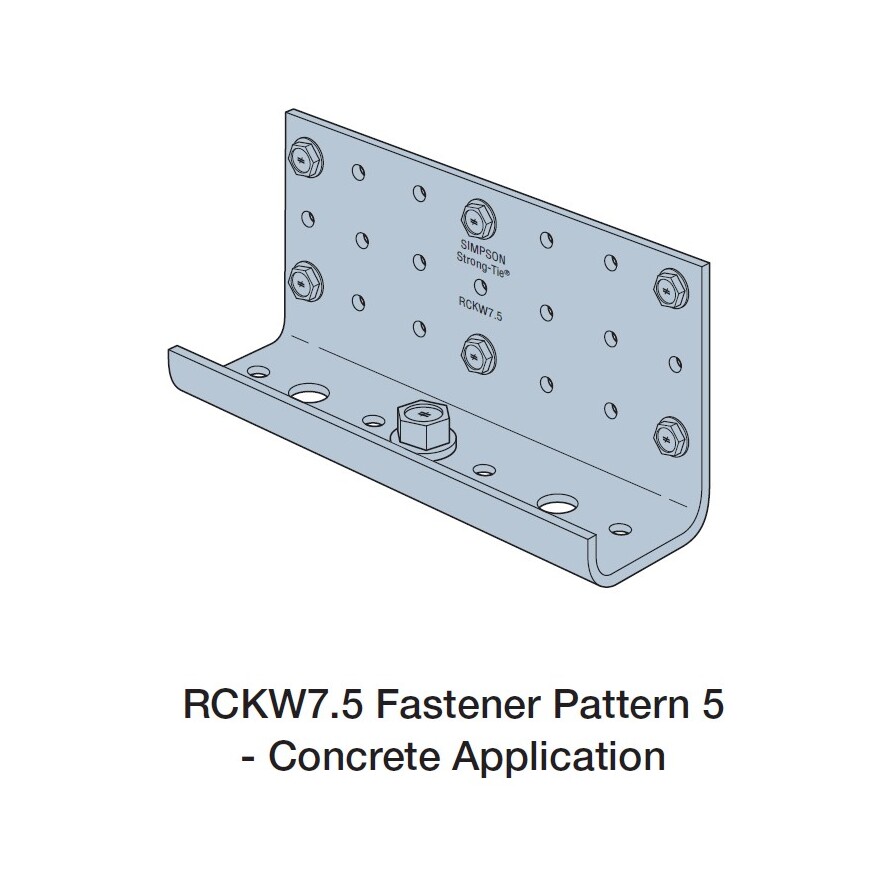

9. See illustrations for fastener pattern placement

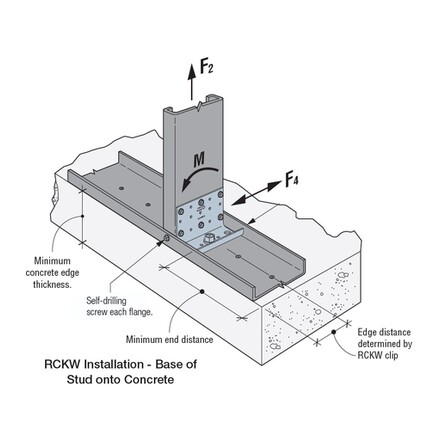

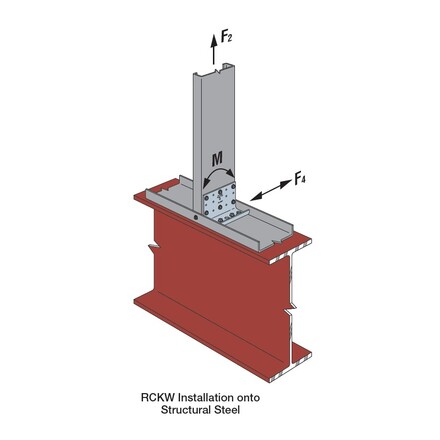

Installation

Installation

Installation

- Use all specified fasteners (see performance tables for fastener quantities and types)

- When using the RCKWS, secure the stiffener to the clip with the specified fasteners. Screws must extend through the connection with a minimum of three exposed threads.

- When installing onto concrete, the installation torque must be as published for the relevant anchor type and size

- When using the larger-diameter anchor holes, the bottom track must be predrilled or punched with a 20mm diameter hole.