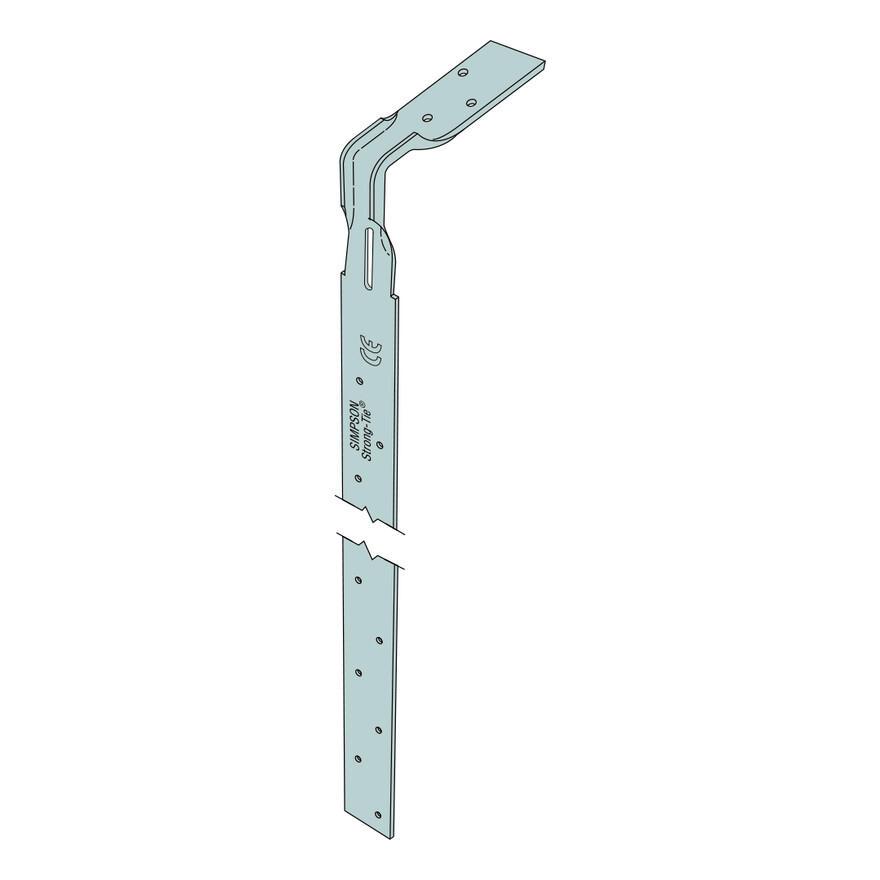

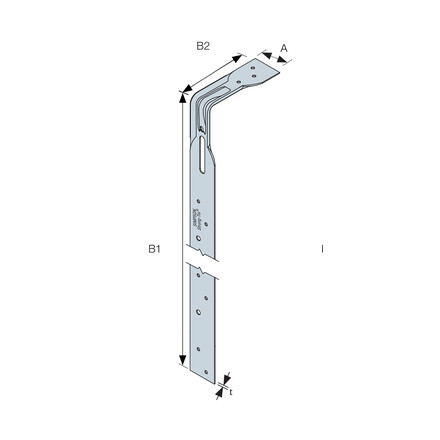

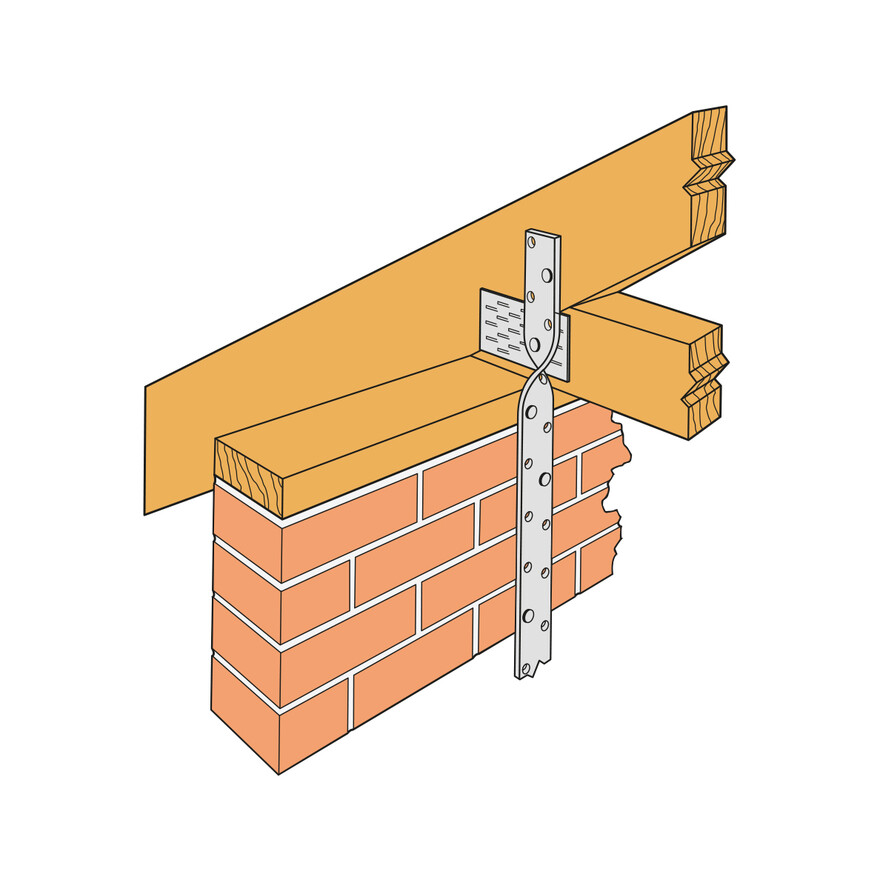

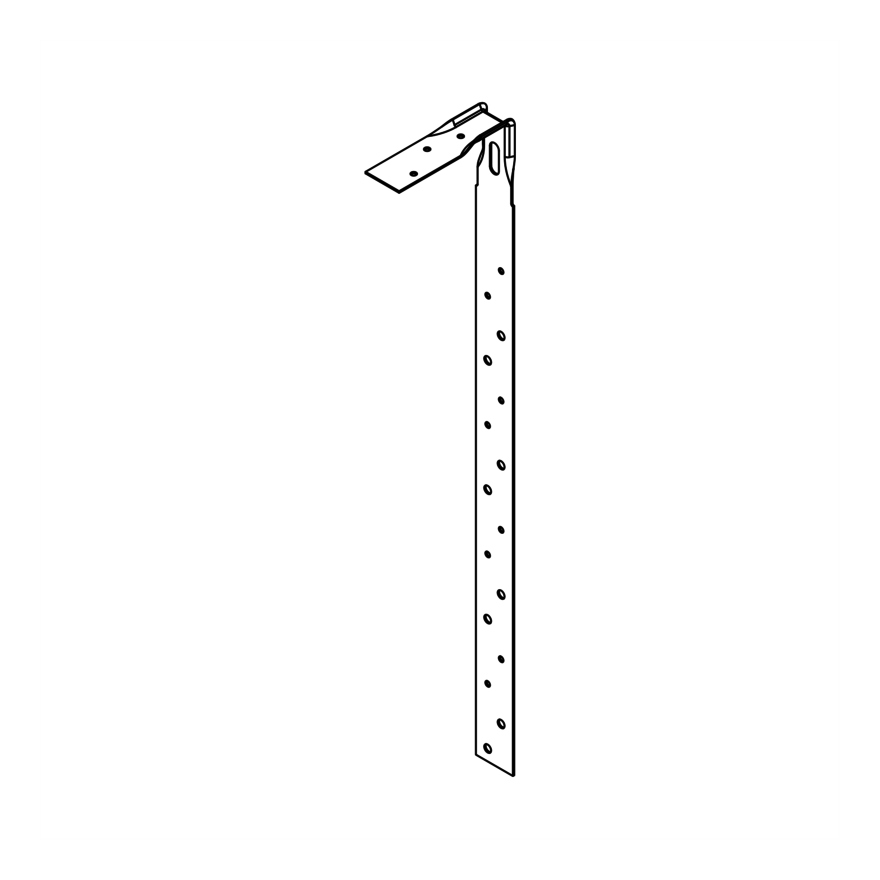

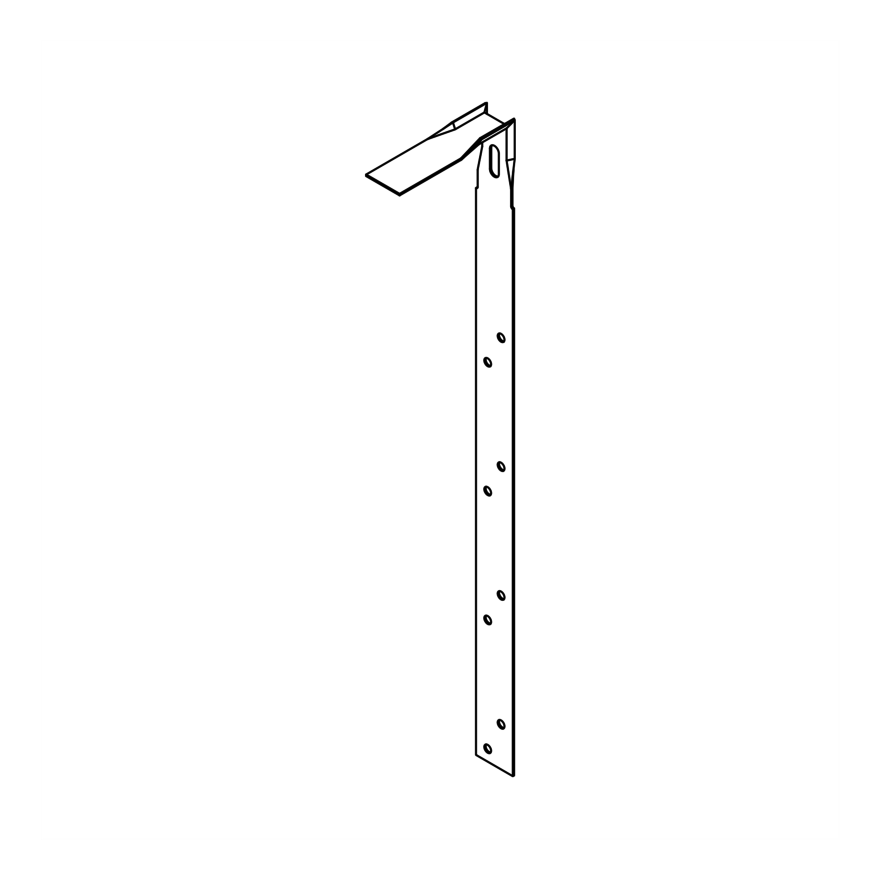

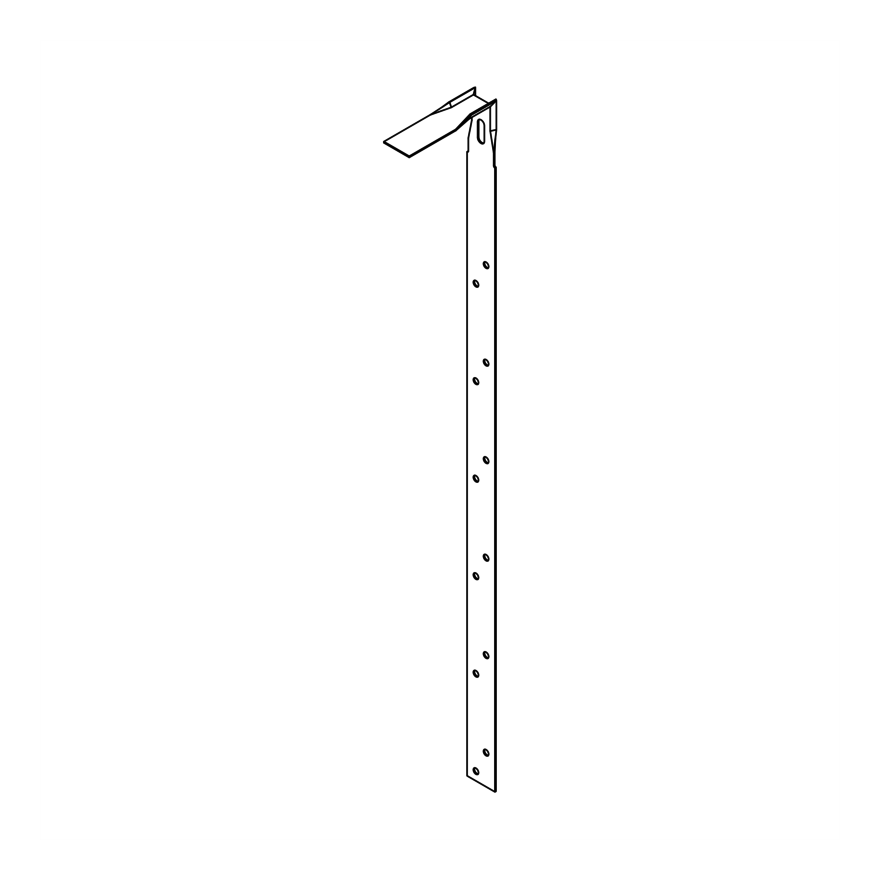

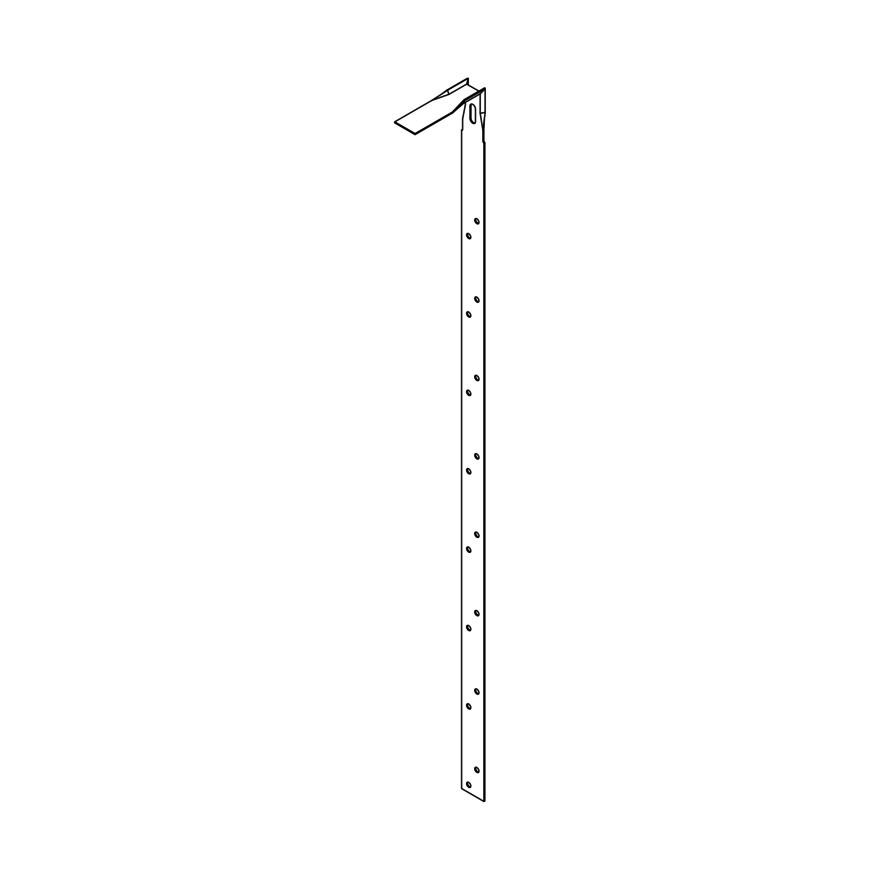

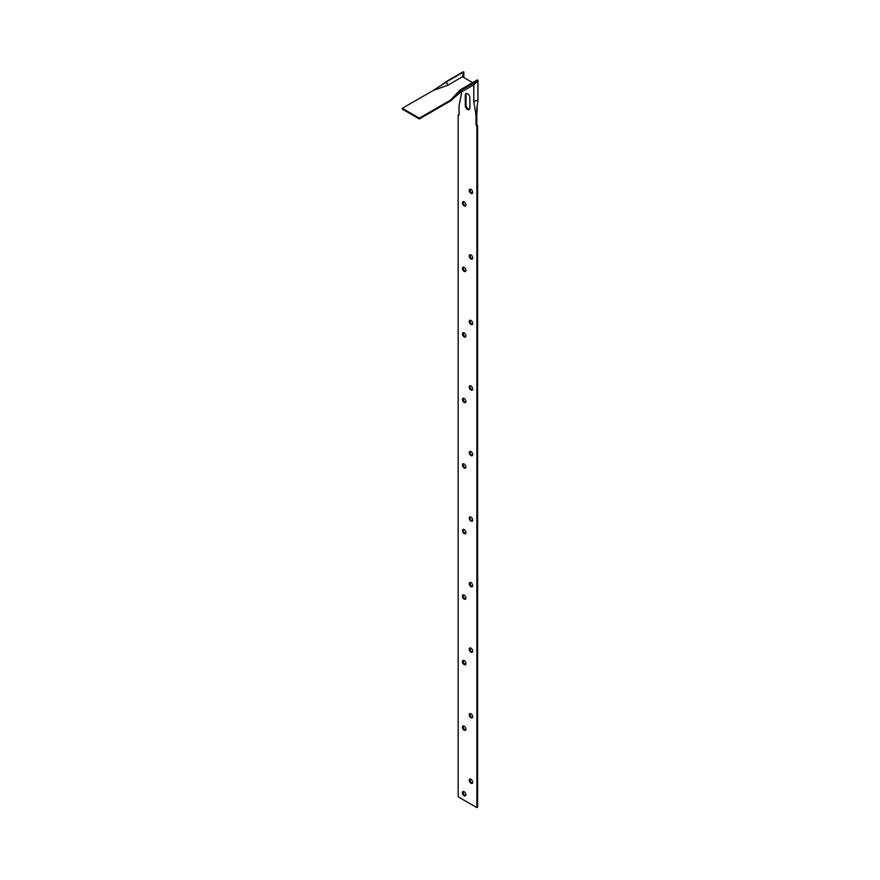

Light Engineered Restraint Strap

A direct replacement for traditional restraint straps, the innovative design of these lightweight straps allows ease of handling and installation whilst maintaining the structural strength and robustness of much heavier weight types.

The HES (heavy engineered strap) & LES (light engineered strap) replace

traditional heavy and light restraint straps in roof and floor construction.

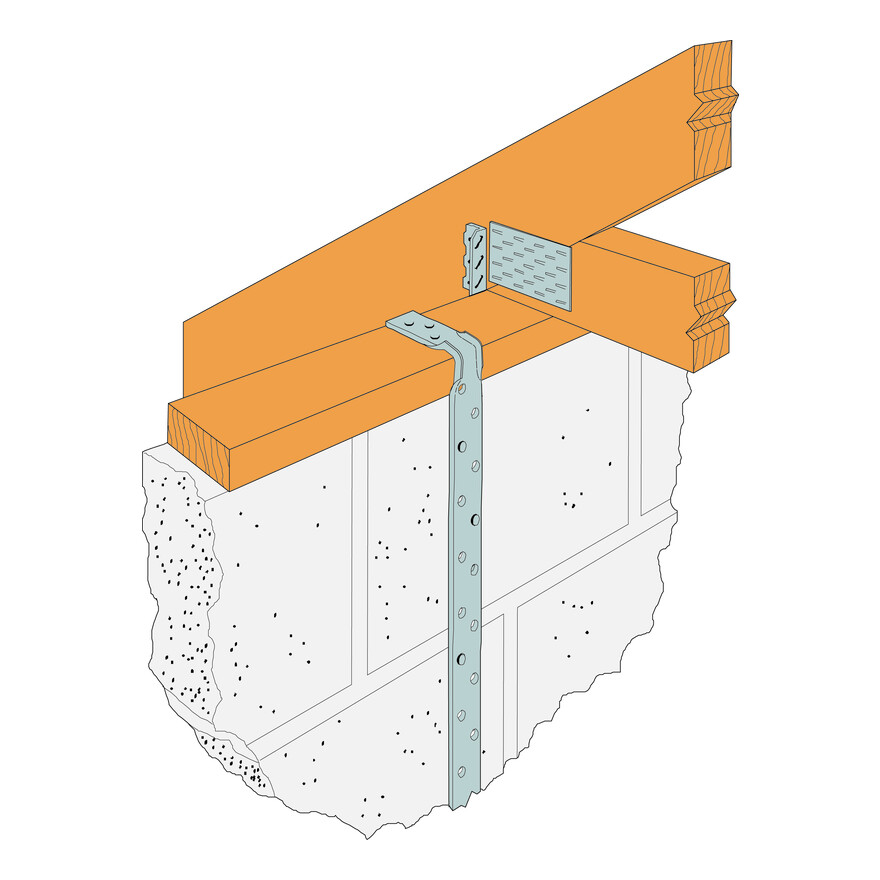

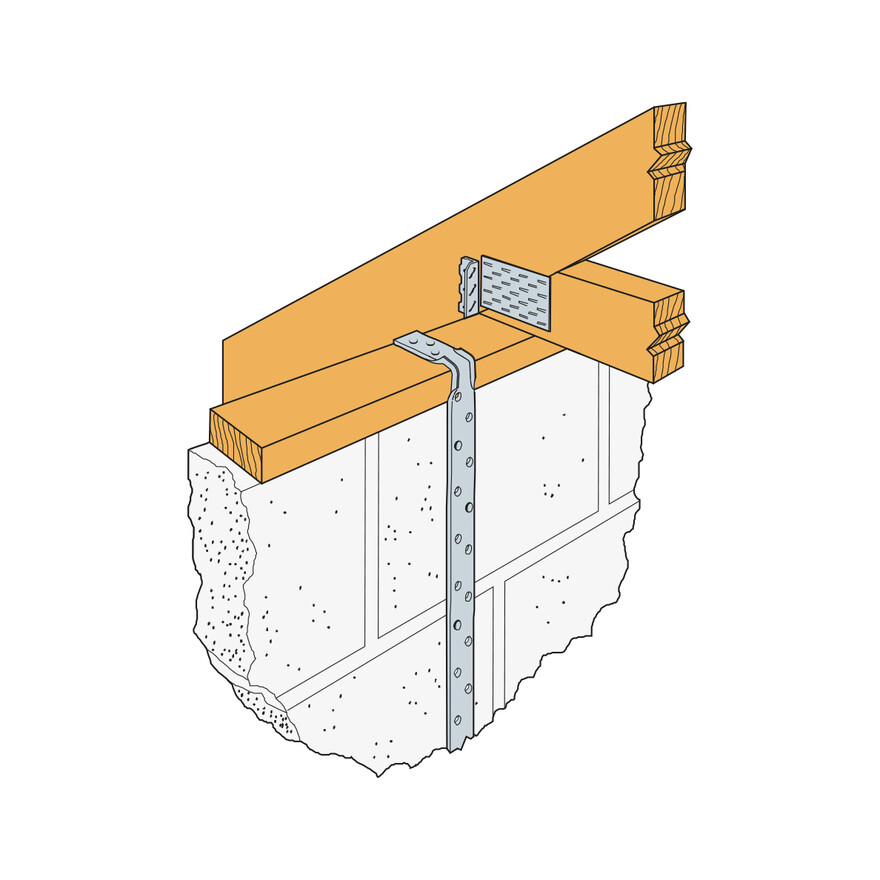

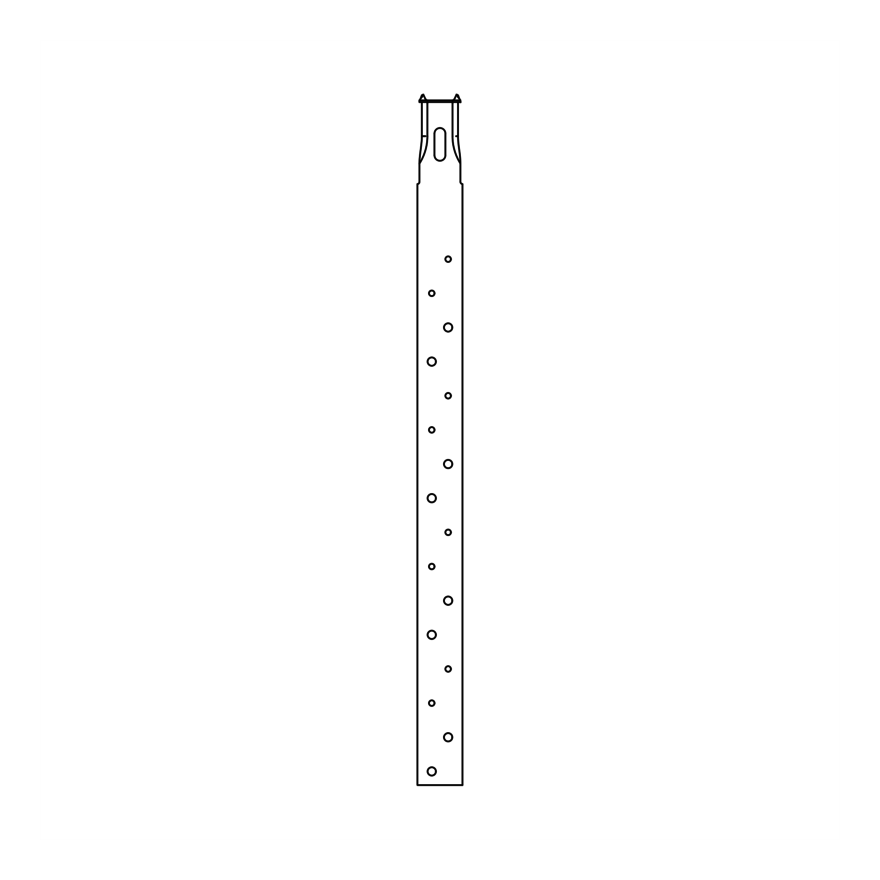

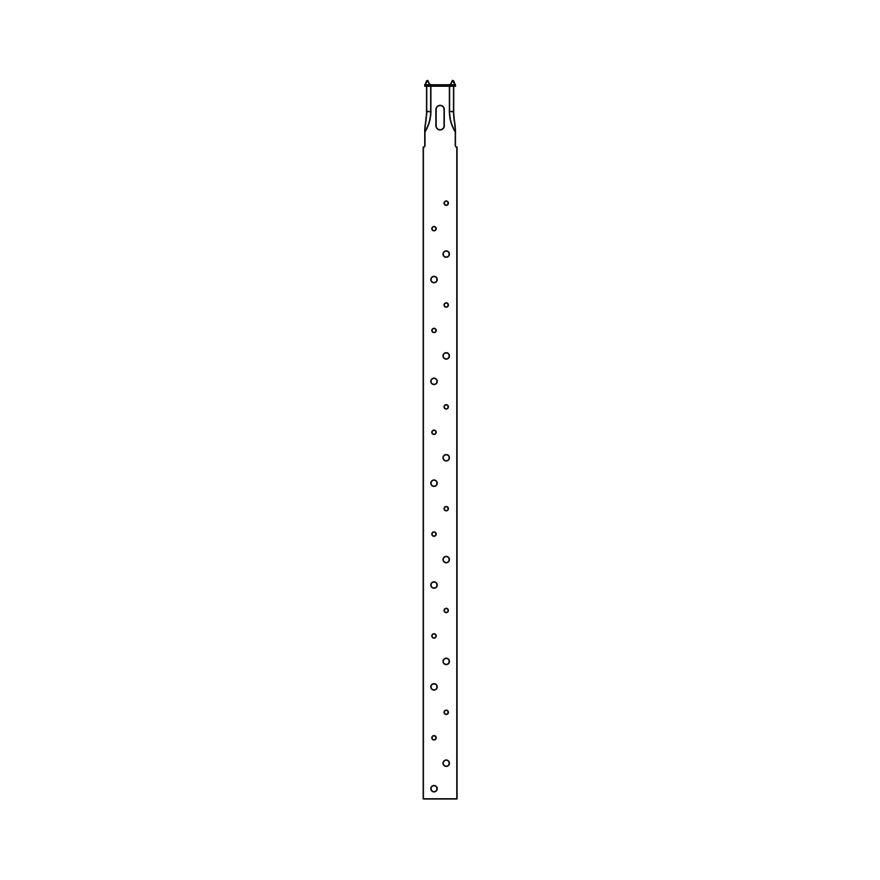

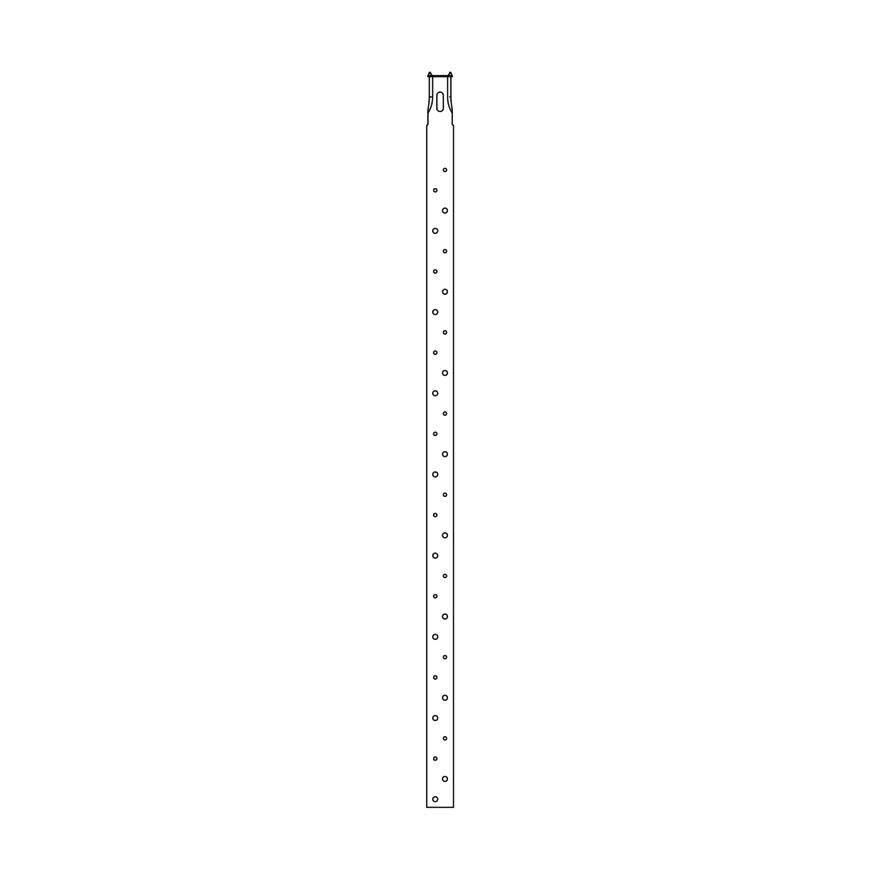

Reducing the thickness allows the LES strap to span the bottom

chords of trusses and over floor joists without the need for notching.

LES straps are less than 40% of the weight, quicker to fit, and overcome many fixing problems associated with traditional heavy straps.

The LES is designed for vertical applications e.g. holding down wall plates.

- Formed edge design gives additional strength on bend

- Quicker to install - can fit over top of floor joists and truss bottom chords

- Easier to course with blockwork

- No need to notch joists

- Complies with BS EN 845-1