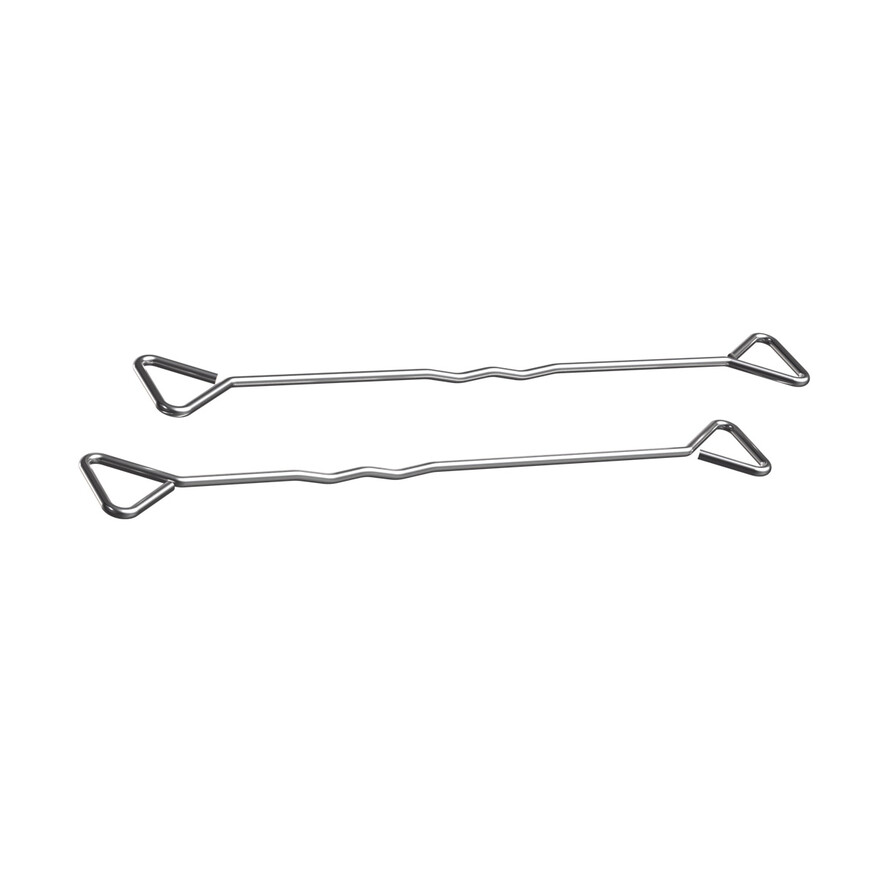

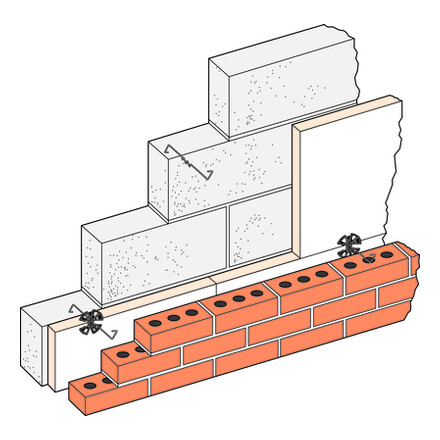

Stainless Steel Wire Wall Tie

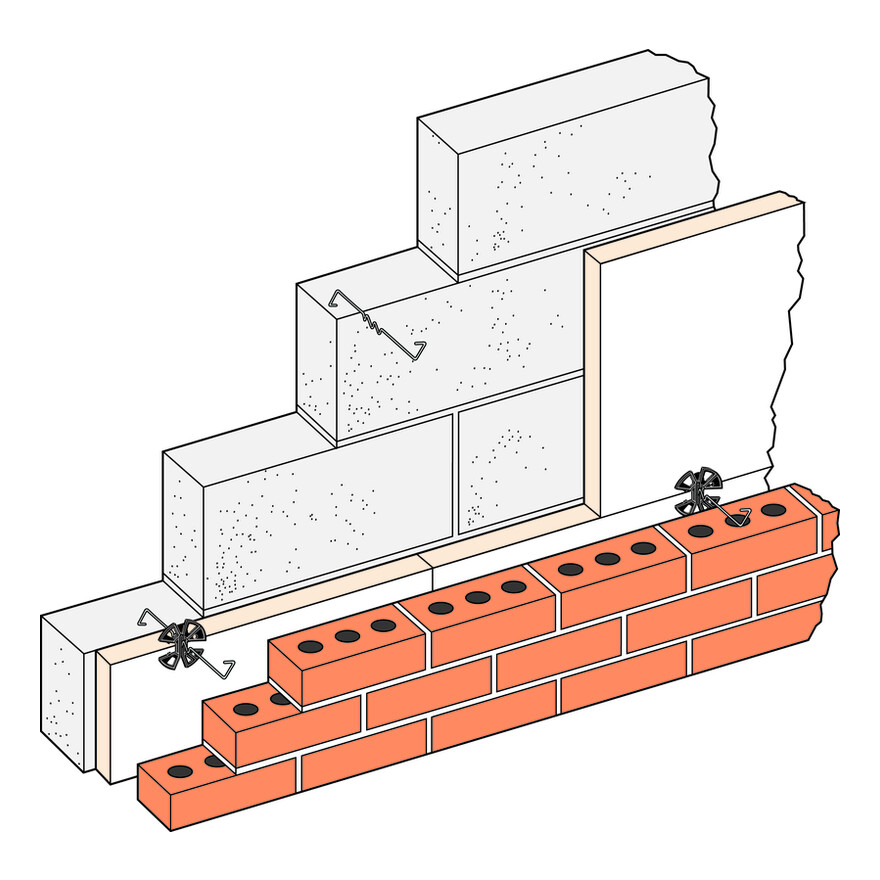

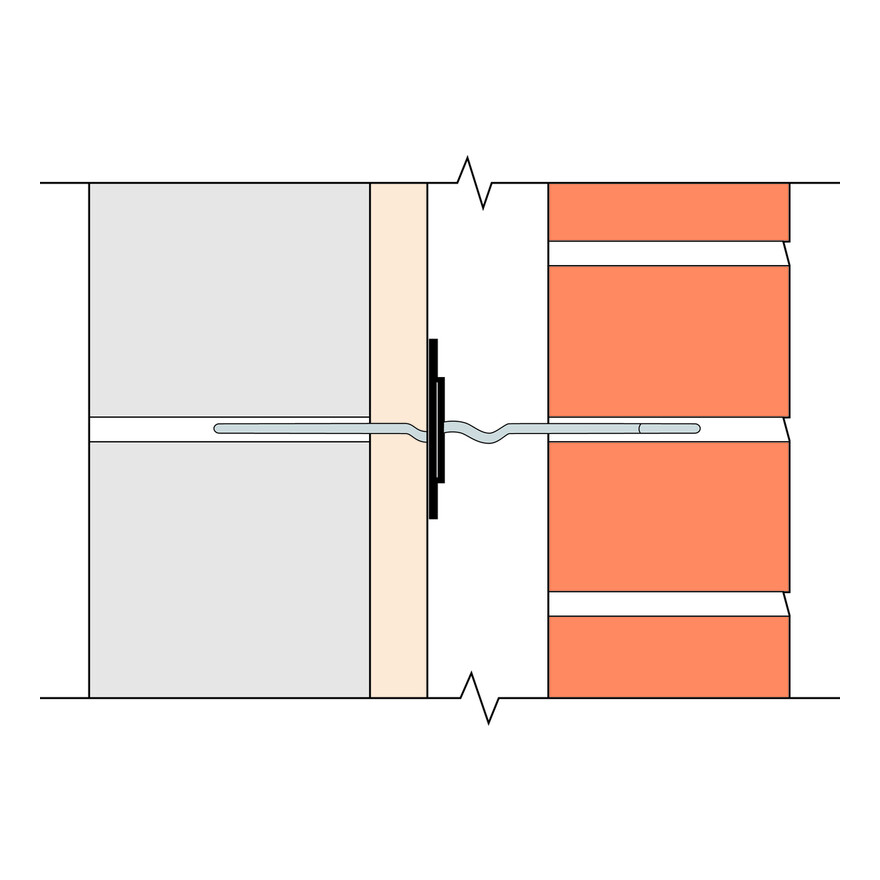

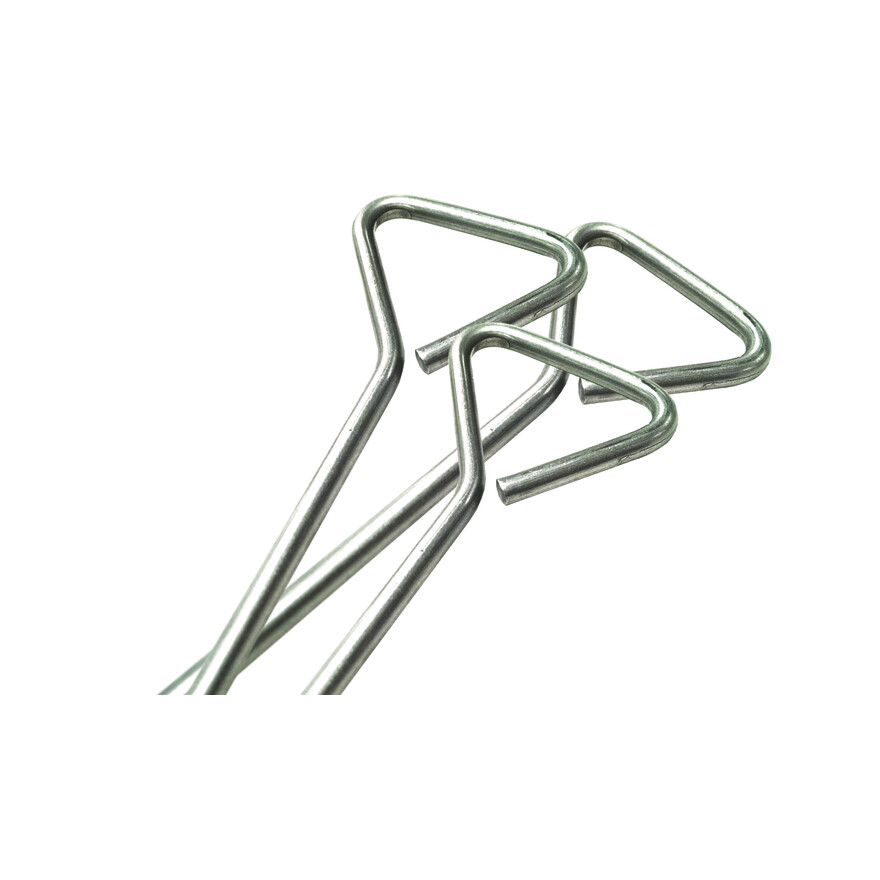

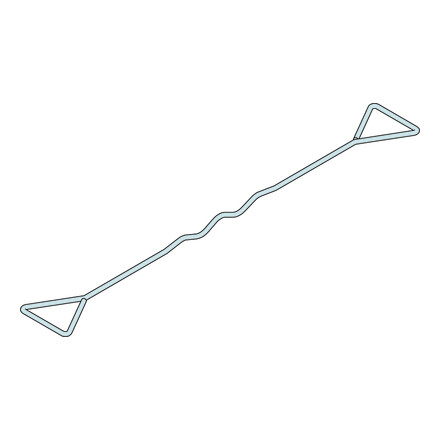

Types 2, 3 and 4 Stainless Steel Masonry to Masonry Wall Ties.

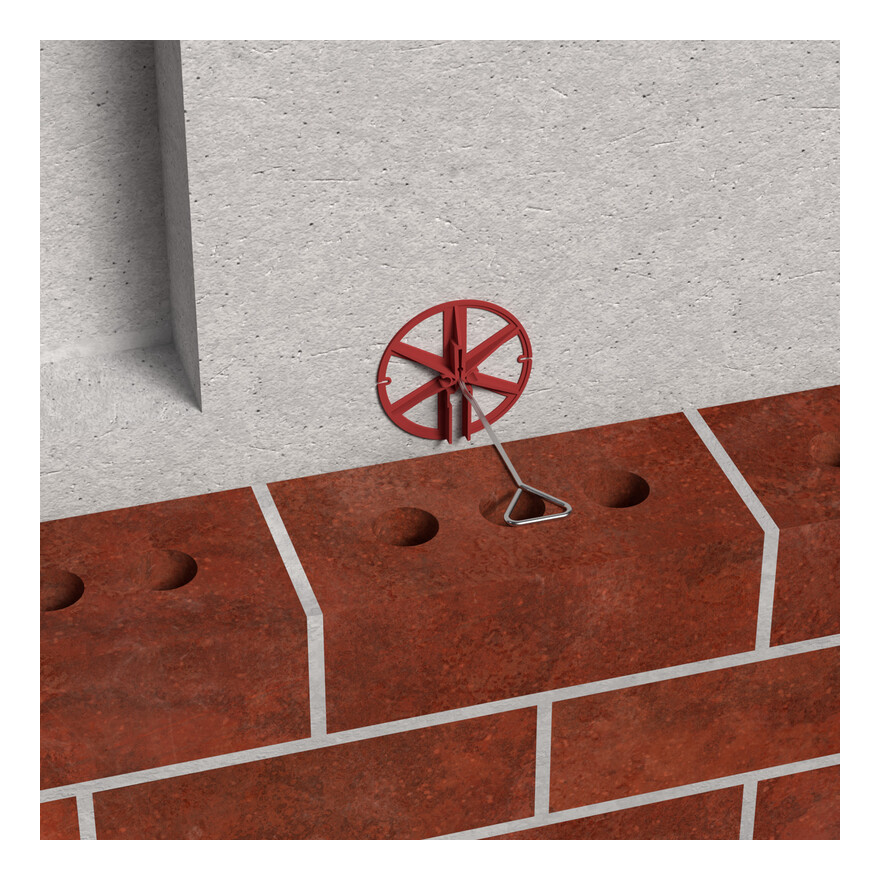

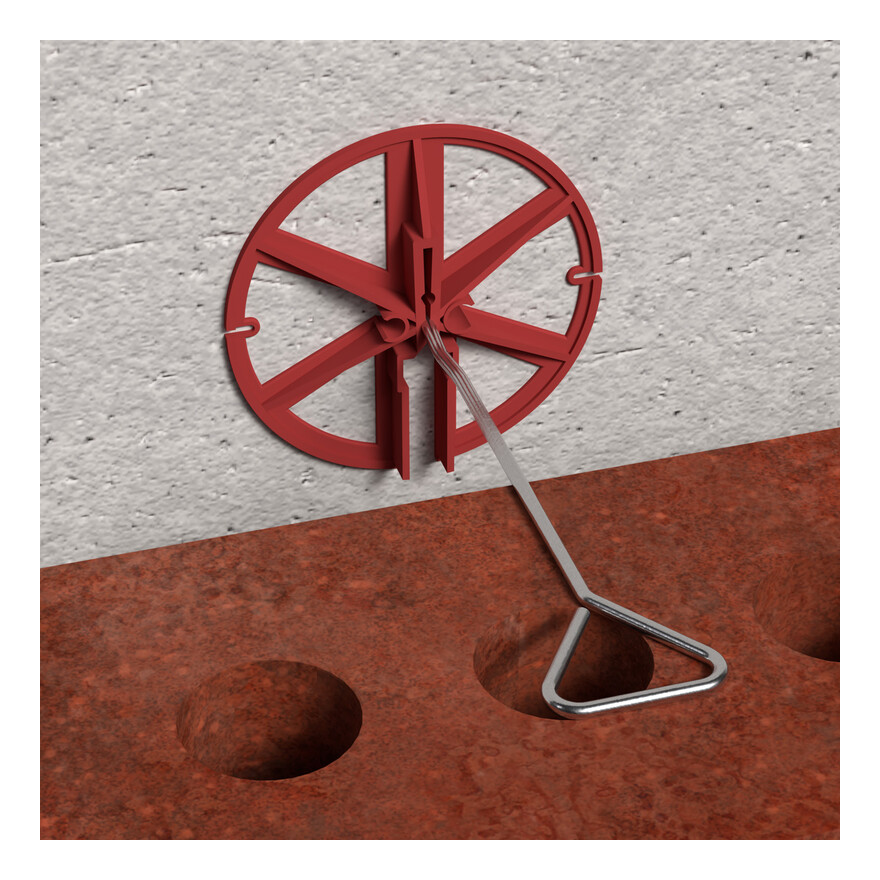

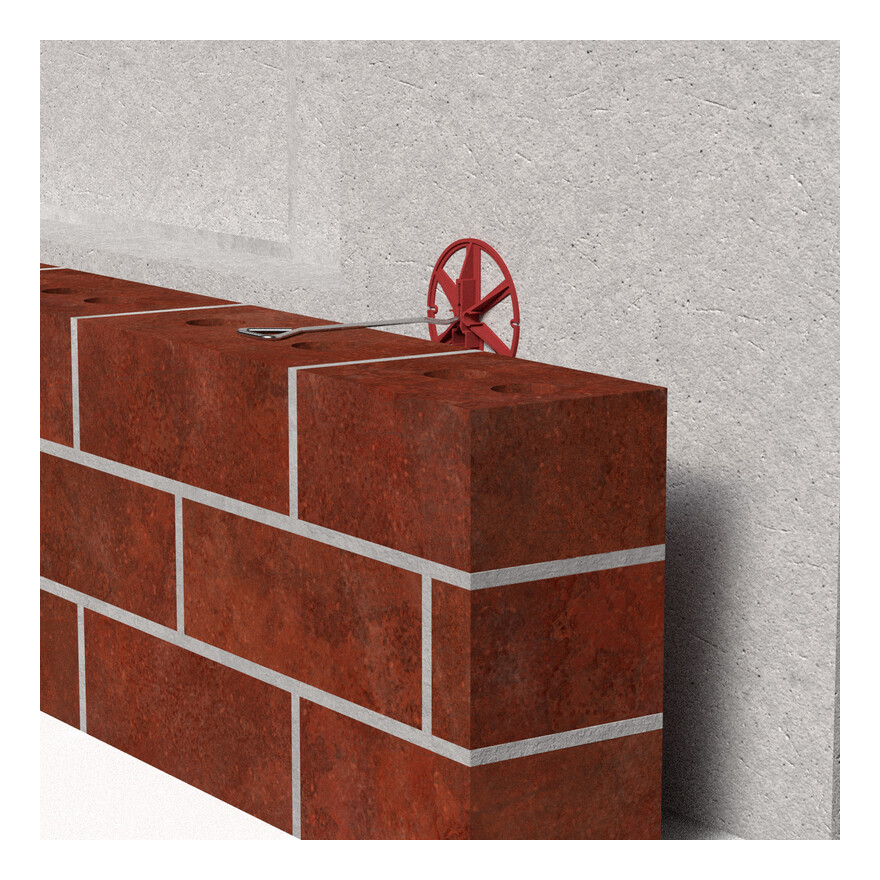

WTS2: Type 2 Wall Ties: Masonry General Purpose

Type 2 wall ties are suitable for general purpose applications such as domestic and small commercial buildings up to 15m in height. They can also be used in buildings with heights exceeding 15m, but should only be used in those situations if shown to be of adequate performance by calculation. Use in flat sites where the basic wind speed is up to 31 m/s and the altitude is not more than 150m above sea level.

WTS3: Type 3 Wall Ties: Masonry General Purpose

As Type 2 but fundamental basic wind velocity limited to 27 m/s

WTS4: Type 4 Wall Ties: Masonry Light Duty

Type 4 wall ties are light duty, suitable for box-form dwellings up to 10 metres high with leaves of similar thickness, including internal separating cavity walls. Use in flat sites in towns and cities where the basic wind speed does not exceed 25 m/s and the altitude is not more than 150m above sea level.

WTS4: Type A Approval

WTS4-200 and WTS4-225 ties meet the requirements of Approved Document E: Resistance to the Passage of Sound and are suitable for use in separating party walls of new build attached dwellings.