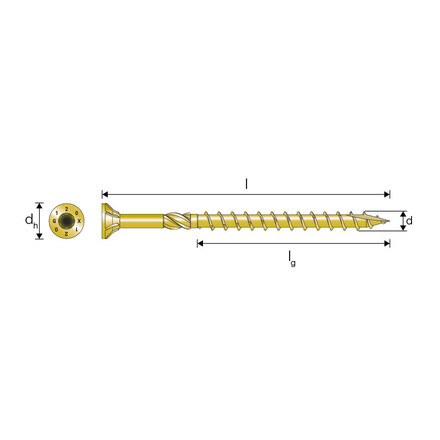

Structural Countersunk Wood Screw

SWC is a countersunk structural screw designed for load-bearing wood structures. The SWC screw has a milling thread to allow for smoothdriving of the shank. The countersunk head gives flush fitting while allowing the wood members to close up firmly.