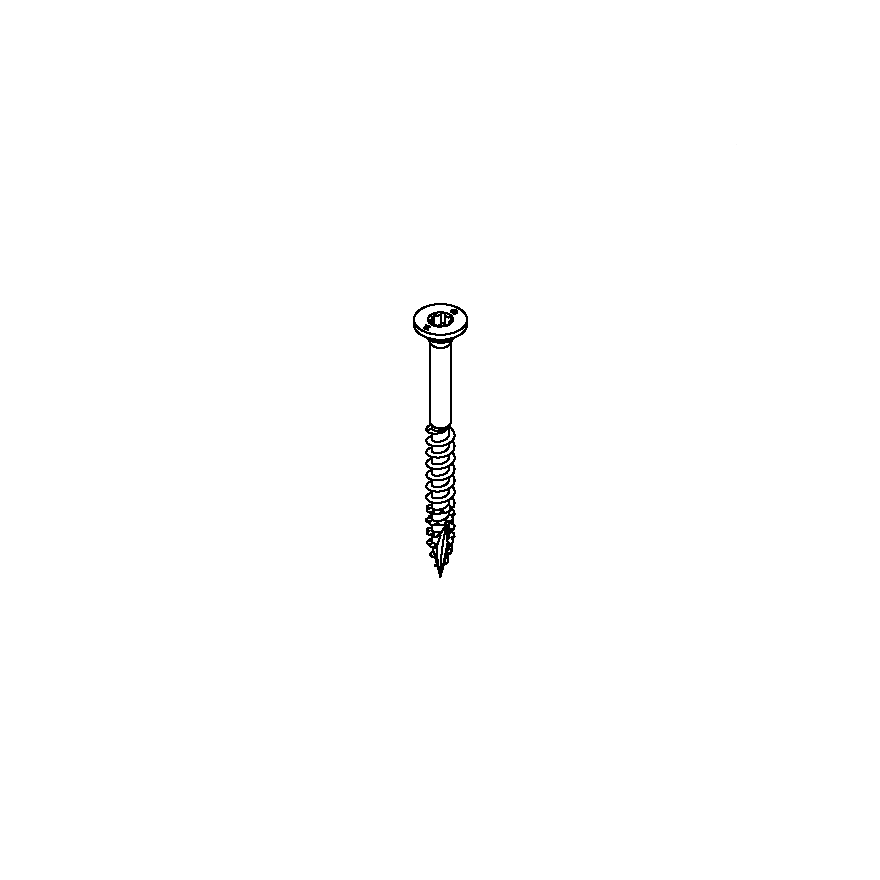

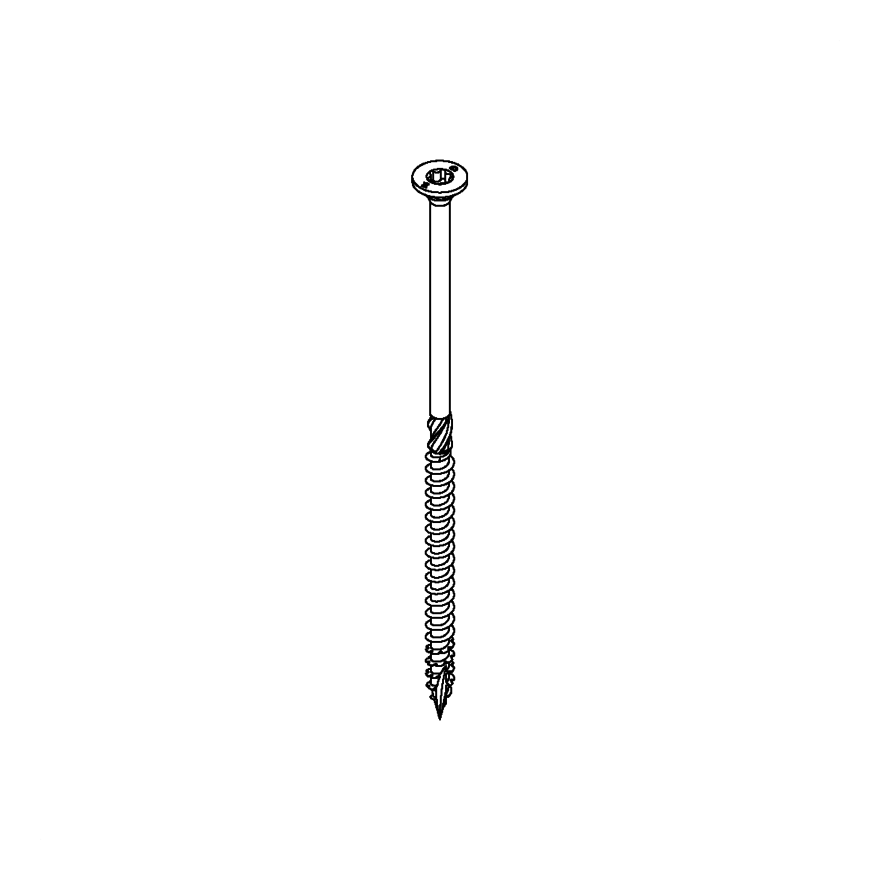

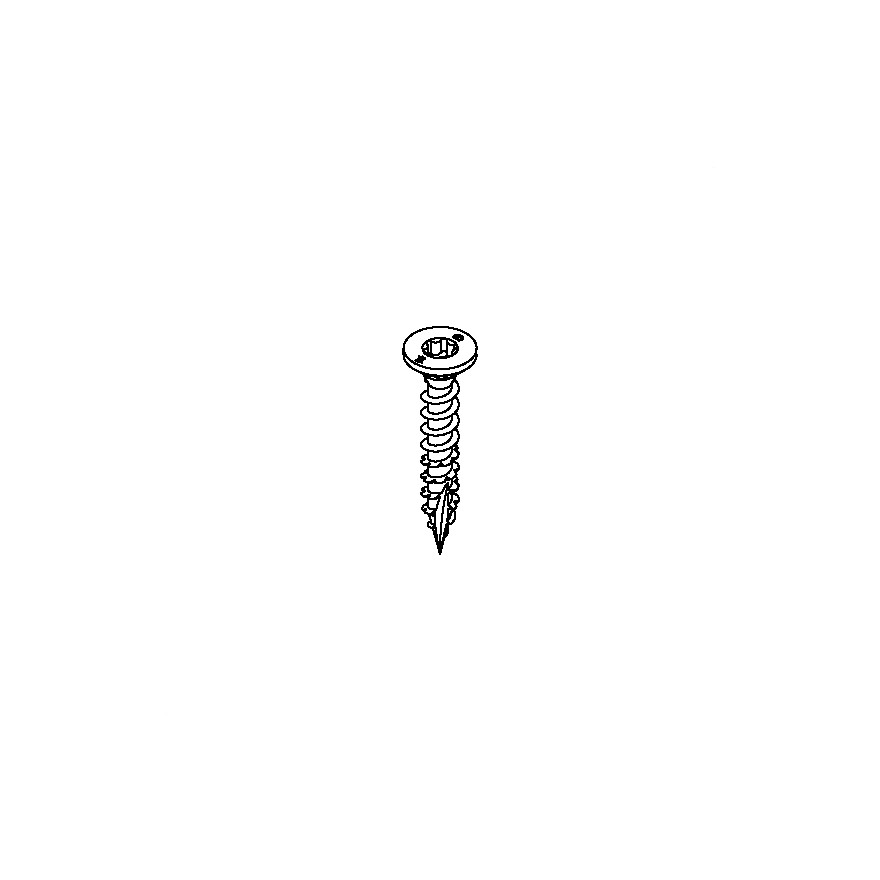

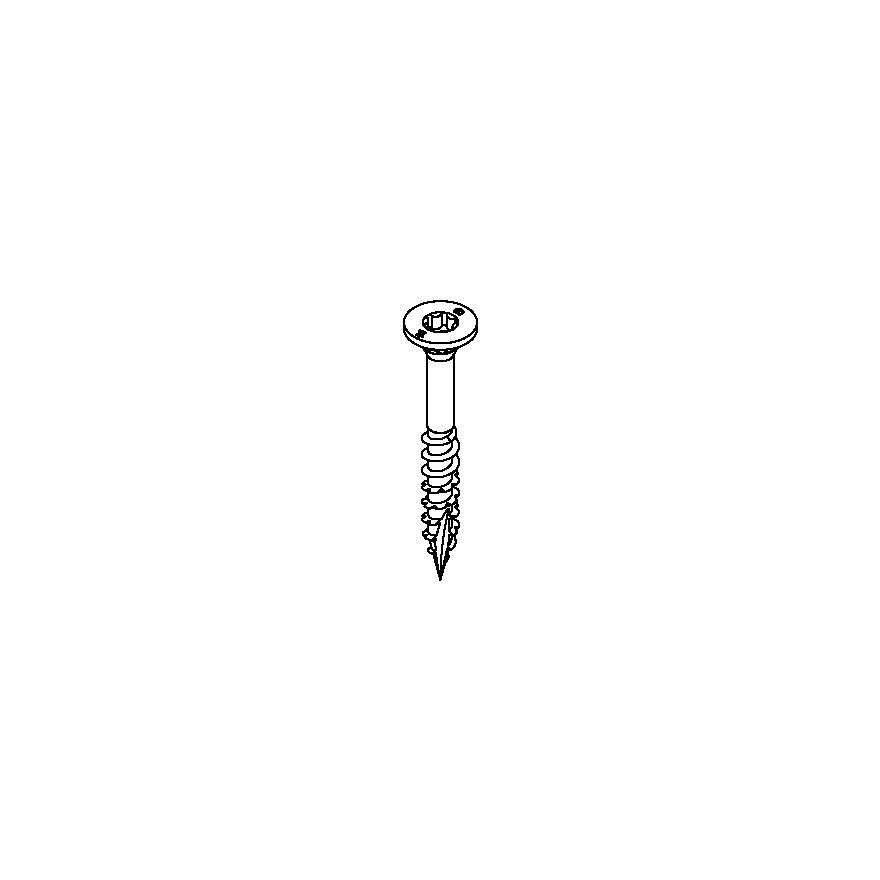

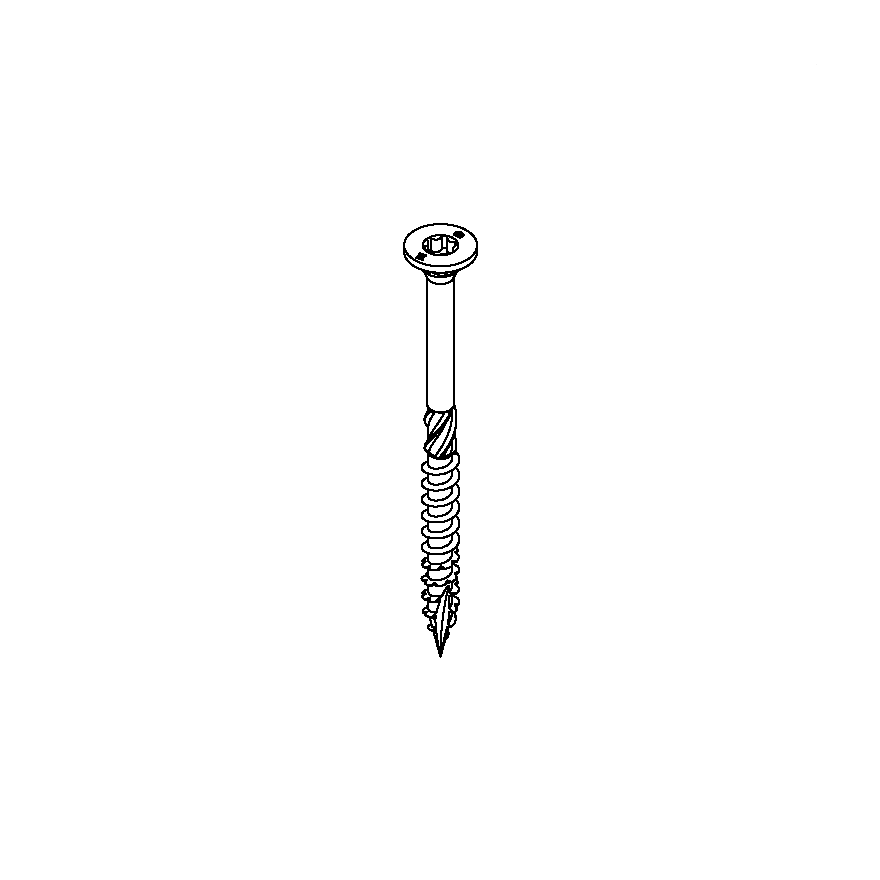

Countersunk Wood Screw - Electro Galvanised

Suitable for interior use, the TTUFS screw has a serrated thread to reduce the resistance when driving.

It has a cut point which prevents cracking.

70mm or longer variants have an additional milling thread to further reduce the resistance.

Technical Data

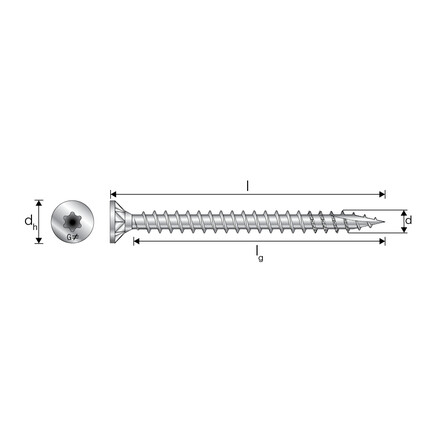

Product Dimensions

| References | Item Code | NOB nr. | Tun / DB nr. | Fastener dimensions [mm] | Weight [kg] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| d | l | dh | d1 | lg | bit | Thread | |||||

| TTUFS4.5X50 PT | 74439 | 53294061 | 1949935 | 4.5 | 50 | 8.4 | 2.8 | 30 | T-20 | TG | 0.003 |

| TTUFS5.0X70 | 74377 | 53294163 | 1949945 | 5 | 70 | 9.5 | 3.1 | 40 | T-25 | VG | 0.006 |

| TTUFS5.0X80 | 74378 | 53294178 | 1949946 | 80 | 9.5 | 3.1 | 40 | T-25 | TGR | 0.006 | |

| TTUFS5.0X90 | 74379 | 53294182 | 1949947 | 90 | 9.5 | 3.1 | 45 | T-25 | TGR | 0.007 | |

| TTUFS5.0X100 | 74443 | 53294106 | 1949939 | 100 | 9.5 | 3.1 | 60 | T-25 | TGR | 0.008 | |

| TTUFS6.0X40 | 74455 | 53294246 | 1949953 | 6 | 40 | 11.6 | 3.7 | 34 | T-30 | VG | 0.005 |

| TTUFS6.0X50 | 74457 | 53294254 | 1949954 | 50 | 11.6 | 3.7 | 30 | T-30 | TG | 0.006 | |

| TTUFS6.0X60 | 74458 | 53294265 | 1949955 | 60 | 11.6 | 3.7 | 35 | T-30 | TG | 0.007 | |

| TTUFS6.0X70 | 74459 | 53294273 | 1949956 | 70 | 11.6 | 3.7 | 40 | T-30 | TG | 0.008 | |

| TTUFS6.0X80 | 74460 | 53294284 | 1949957 | 80 | 11.6 | 3.7 | 40 | T-30 | TGR | 0.01 | |

| TTUFS6.0X90 | 74461 | 53294292 | 1949958 | 90 | 11.6 | 3.7 | 45 | T-30 | TGR | 0.011 | |

| TTUFS6.0X100 | 74380 | 53294197 | 1949948 | 100 | 11.6 | 3.7 | 60 | T-30 | TGR | 0.012 | |

| TTUFS6.0X120 | 74451 | 53294201 | 1949949 | 120 | 11.6 | 3.7 | 70 | T-30 | TGR | 0.015 | |

| TTUFS6.0X140 | 74452 | 53294216 | 1949950 | 140 | 11.6 | 3.7 | 70 | T-30 | TGR | 0.016 | |

| TTUFS6.0X160 | 74453 | 53294220 | 1949951 | 160 | 11.6 | 3.7 | 70 | T-30 | TGR | 0.018 | |

| TTUFS6.0X180 | 74454 | 53294235 | 1949952 | 180 | 11.6 | 3.7 | 70 | T-30 | TGR | 0.021 | |

Diameters 3.0, 3.5 and 4.0 screws are not CE marked.

FT = Full Thread

PT = Partial Thread

PTM = Parial Thread with Milling Thread

Product characteristic properties

| References | Characteristic Yield Moment – My,k [Nmm] | Characteristic withdrawal parameter - fax,k,90° [N/mm²] | Characteristic head pull-through parameter - fhead,k [N/mm²] | Characteristic tensile capacity - ftens,k [kN] |

|---|---|---|---|---|

| TTUFS4.5X50 PT | 4660 | 14.7 | 15.6 | 7.8 |

| TTUFS5.0X70 | 6720 | 15 | 17.1 | 7.9 |

| TTUFS5.0X80 | 6720 | 15 | 17.1 | 7.9 |

| TTUFS5.0X90 | 6720 | 15 | 17.1 | 7.9 |

| TTUFS5.0X100 | 6720 | 15 | 17.1 | 7.9 |

| TTUFS6.0X40 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X50 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X60 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X70 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X80 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X90 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X100 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X120 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X140 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X160 | 9500 | 12.5 | 16.6 | 11.1 |

| TTUFS6.0X180 | 9500 | 12.5 | 16.6 | 11.1 |

Refer to relevant ITTR or ETA for more details

Installation

Installation

Spacing and Edge distances - Shear loaded screws

| References | Minimum edge distances and spacing for shear loaded screws [mm] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Angle between load and grain = 0° | Angle between load and grain = 90° | |||||||||||

| a1.0 | a2.0 | a3.t.0 | a3.c.0 | a4.t.0 | a4.c.0 | a1.90 | a2.90 | a3.t.90 | a3.c.90 | a4.t.90 | a4.c.90 | |

| TTUFS4.5X50 PT | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS5.0X70 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS5.0X80 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS5.0X90 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS5.0X100 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X40 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X50 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X60 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X70 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X80 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X90 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X100 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X120 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X140 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X160 | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X180 | - | - | - | - | - | - | - | - | - | - | - | - |

a1 and a2 can be multiplied by 0.85 for panel/timber assembly, and by 0.7 for steel/timber assembly.

Spacing and edge distances - Axially loaded screws

| References | Minimum edge distances and spacing for axially loaded screws [mm] | |||

|---|---|---|---|---|

| a1 | a2 | a3.c | a4.c | |

| TTUFS4.5X50 PT | - | - | - | - |

| TTUFS5.0X70 | - | - | - | - |

| TTUFS5.0X80 | - | - | - | - |

| TTUFS5.0X90 | - | - | - | - |

| TTUFS5.0X100 | - | - | - | - |

| TTUFS6.0X40 | - | - | - | - |

| TTUFS6.0X50 | - | - | - | - |

| TTUFS6.0X60 | - | - | - | - |

| TTUFS6.0X70 | - | - | - | - |

| TTUFS6.0X80 | - | - | - | - |

| TTUFS6.0X90 | - | - | - | - |

| TTUFS6.0X100 | - | - | - | - |

| TTUFS6.0X120 | - | - | - | - |

| TTUFS6.0X140 | - | - | - | - |

| TTUFS6.0X160 | - | - | - | - |

| TTUFS6.0X180 | - | - | - | - |

Abacus

Timber to Timber characteristic capacities

| References | Product characteristic capacities - Timber to Timber C24 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Axial resistance | Shear resistance parallel to the grain depending of t1 [Rv.0.k] [kN] | Shear resistance perpendicular to the grain depending of t1 [Rv.90.k] [kN] | ||||||||||||||

| t1 [mm] | Rax.k [kN] | 35 [mm] | 40 [mm] | 45 [mm] | 60 [mm] | 75 [mm] | 80 [mm] | ≥100 [mm] | 35 [mm] | 40 [mm] | 45 [mm] | 60 [mm] | 75 [mm] | 80 [mm] | ≥100 [mm] | |

| TTUFS5.0X80 | 40 | 1.64 | 1.64 | 1.64 | 1.64 | - | - | - | - | 1.64 | 1.64 | 1.64 | - | - | - | - |

| TTUFS5.0X90 | 45 | 1.64 | 1.64 | 1.64 | 1.64 | - | - | - | - | 1.64 | 1.64 | 1.64 | - | - | - | - |

| TTUFS5.0X100 | 40 | 1.64 | 1.64 | 1.64 | 1.64 | - | - | - | - | 1.64 | 1.64 | 1.64 | - | - | - | - |

| TTUFS6.0X80 | 40 | 2.73 | 2.09 | 2.09 | 2.15 | - | - | - | - | 2.09 | 2.09 | 2.15 | - | - | - | - |

| TTUFS6.0X90 | 45 | 2.73 | 2.09 | 2.09 | 2.15 | - | - | - | - | 2.09 | 2.09 | 2.15 | - | - | - | - |

| TTUFS6.0X100 | 40 | 2.73 | 2.09 | 2.09 | 2.15 | - | - | - | - | 2.09 | 2.09 | 2.15 | - | - | - | - |

| TTUFS6.0X120 | 50 | 2.73 | 2.09 | 2.09 | 2.15 | - | - | - | - | 2.09 | 2.09 | 2.15 | - | - | - | - |

| TTUFS6.0X140 | 70 | 2.73 | 2.09 | 2.09 | 2.15 | 2.15 | 2.15 | - | - | 2.09 | 2.09 | 2.15 | 2.15 | 2.15 | - | - |

| TTUFS6.0X160 | 90 | 2.73 | 2.09 | 2.09 | 2.15 | 2.15 | 2.15 | 2.15 | - | 2.09 | 2.09 | 2.15 | 2.15 | 2.15 | 2.15 | - |

| TTUFS6.0X180 | 110 | 2.73 | 2.09 | 2.09 | 2.15 | 2.15 | 2.15 | 2.15 | 2.15 | 2.09 | 2.09 | 2.15 | 2.15 | 2.15 | 2.15 | 2.15 |

These capacities are valid for:

- Timber element under the head with thickness ≤ t1 disclosed in adjacent column

- Screw axis between 45° and 90° from timber grain for ESCR(XXX), and 90° from timber grain for all other screws.

For tightening screws (partially threaded), t1 dimension is the maximum thickness of the under-head timber member for which the thread is fully in the pointside timber member, for an optimum installation and tightening.

The shear capacities are given for several timber thicknesses t1 of the under-head member under the following configurations:

- Load axis at 0° from both timber grains Rv.0°.k

- Load axis at 90° from both timber grains Rv.90°.k

These capacities are valid for C24 timber grades or higher

The pre-drilled hypothesis for capacity and distances calculation is fulfilled.

For partial threaded screws, capacities are only given for configurations where the thread is less than 5mm in under-head timber member, in order to achieve optimum installation and tightening.

Clause (2) in 8.3.1.2 from EN1995-1-1:2004+A2:2014 about embedment length is ignored in these calculations.

Steel to Timber characteristic capacities

| References | Product characteristic capacities - Steel to Timber C24 | ||||

|---|---|---|---|---|---|

| Axial resistance [Rax.st.k] [kN] | Shear resistance - Thin plate | Shear Resistance - Thick steel | |||

| Rv.0.st.k [kN] | Rv.90.st.k [kN] | Rv.0.st.k [kN] | Rv.90.st.k [kN] | ||

| TTUFS4.5X50 PT | 2.59 | 1.66 | 1.66 | 2.22 | 2.22 |

| TTUFS5.0X70 | 2.64 | 2.06 | 2.06 | 2.64 | 2.64 |

| TTUFS5.0X80 | 2.64 | 2.06 | 2.06 | 2.64 | 2.64 |

| TTUFS5.0X90 | 2.97 | 2.14 | 2.14 | 2.72 | 2.72 |

| TTUFS5.0X100 | 3.96 | 2.39 | 2.39 | 2.97 | 2.97 |

| TTUFS6.0X40 | 3.51 | 1.74 | 1.74 | 3.05 | 3.05 |

| TTUFS6.0X50 | 3.1 | 2.2 | 2.2 | 3.33 | 3.33 |

| TTUFS6.0X60 | 3.61 | 2.66 | 2.66 | 3.64 | 3.64 |

| TTUFS6.0X70 | 4.13 | 2.96 | 2.96 | 3.76 | 3.76 |

| TTUFS6.0X80 | 4.13 | 2.96 | 2.96 | 3.76 | 3.76 |

| TTUFS6.0X90 | 4.64 | 3.09 | 3.09 | 3.89 | 3.89 |

| TTUFS6.0X100 | 6.19 | 3.48 | 3.48 | 4.28 | 4.28 |

| TTUFS6.0X120 | 7.22 | 3.74 | 3.74 | 4.54 | 4.54 |

| TTUFS6.0X140 | 7.22 | 3.74 | 3.74 | 4.54 | 4.54 |

| TTUFS6.0X160 | 7.22 | 3.74 | 3.74 | 4.54 | 4.54 |

| TTUFS6.0X180 | 7.22 | 3.74 | 3.74 | 4.54 | 4.54 |

Shear capacities are given for thick (tst = d) and thin (tst = 0,5xd) steel plates under the following configurations:

- Load axis at 0° from timber grain Rv.0°.k

- Load axis at 90° from timber grain Rv.90°.k

These capacities are valid for C24 timber grades or higher.

For intermediate steel thicknesses, capacities shall be calculated by linear interpolation between the limiting thin and thick plate values.

The pre-drilled hypothesis for capacity and distances calculation is fulfilled.

Ledger on stud characteristic capacities

| References | Product characteristic capacities - Ledger on stud C24 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum width of the stud [mm] | Minimum distance to the bottom side of the ledger a4,c [mm] | Shear capacity depending of thickness of ledger t1 [Rv.90-0.k] [kN] | ||||||||

| 35 [mm] | 40 [mm] | 45 [mm] | 60 [mm] | 75 [mm] | 80 [mm] | 90 [mm] | ≥100 [mm] | |||

| TTUFS4.5X50 PT | - | - | - | - | - | - | - | - | - | - |

| TTUFS5.0X70 | 30 | 15 | 1.81 | - | - | - | - | - | - | - |

| TTUFS5.0X80 | 30 | 15 | 1.81 | 1.81 | 1.81 | - | - | - | - | - |

| TTUFS5.0X90 | 30 | 15 | 1.81 | 1.81 | 1.81 | - | - | - | - | - |

| TTUFS5.0X100 | 30 | 15 | 1.81 | 1.81 | 1.81 | - | - | - | - | - |

| TTUFS6.0X40 | 36 | 18 | - | - | - | - | - | - | - | - |

| TTUFS6.0X50 | 36 | 18 | - | - | - | - | - | - | - | - |

| TTUFS6.0X60 | 36 | 18 | - | - | - | - | - | - | - | - |

| TTUFS6.0X70 | 36 | 18 | 2.44 | - | - | - | - | - | - | - |

| TTUFS6.0X80 | 36 | 18 | 2.62 | 2.6 | 2.44 | - | - | - | - | - |

| TTUFS6.0X90 | 36 | 18 | 2.62 | 2.62 | 2.62 | - | - | - | - | - |

| TTUFS6.0X100 | 36 | 18 | 2.62 | 2.62 | 2.62 | - | - | - | - | - |

| TTUFS6.0X120 | 36 | 18 | 2.62 | 2.62 | 2.62 | - | - | - | - | - |

| TTUFS6.0X140 | 36 | 18 | 2.62 | 2.62 | 2.62 | 2.62 | 2.62 | - | - | - |

| TTUFS6.0X160 | 36 | 18 | 2.62 | 2.62 | 2.62 | 2.62 | 2.62 | 2.62 | 2.62 | - |

| TTUFS6.0X180 | 36 | 18 | 2.62 | 2.62 | 2.62 | 2.62 | 2.62 | 2.62 | 2.62 | 2.62 |

The pre-drilled hypothesis for capacity and distances calculation is fulfilled.

Panel to Timber characteristic capacities

| References | Panel (OSB, Fibreboard ρk≥380 kg/m3) on Timber C24 depending on panel thickness tp | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 13 [mm] | 15 [mm] | 18 [mm] | 22 [mm] | 25 [mm] | |||||||||||

| Rax.k.13 [kN] | Rv.0.k.13 [kN] | Rv.90.k.13 [kN] | Rax.k.15 [kN] | Rv.0.k.15 [kN] | Rv.90.k.15 [kN] | Rax.k.18 [kN] | Rv.0.k.18 [kN] | Rv.90.k.18 [kN] | Rax.k.22 [kN] | Rv.0.k.22 [kN] | Rv.90.k.22 [kN] | Rax.k.25 [kN] | Rv.0.k.25 [kN] | Rv.90.k.25 [kN] | |

| TTUFS4.5X50 PT | 0.56 | 0.84 | 0.84 | 0.56 | 0.88 | 0.88 | 0.56 | 0.94 | 0.94 | 0.71 | 1.06 | 1.06 | 0.71 | 1.06 | 1.06 |

| TTUFS5.0X70 | 0.72 | 1.03 | 1.03 | 0.72 | 1.06 | 1.06 | 0.72 | 1.11 | 1.11 | 0.9 | 1.24 | 1.24 | 0.9 | 1.31 | 1.31 |

| TTUFS5.0X80 | 0.72 | 1.03 | 1.03 | 0.72 | 1.06 | 1.06 | 0.72 | 1.11 | 1.11 | 0.9 | 1.24 | 1.24 | 0.9 | 1.31 | 1.31 |

| TTUFS5.0X90 | 0.72 | 1.03 | 1.03 | 0.72 | 1.06 | 1.06 | 0.72 | 1.11 | 1.11 | 0.9 | 1.24 | 1.24 | 0.9 | 1.31 | 1.31 |

| TTUFS5.0X100 | 0.72 | 1.03 | 1.03 | 0.72 | 1.06 | 1.06 | 0.72 | 1.11 | 1.11 | 0.9 | 1.24 | 1.24 | 0.9 | 1.31 | 1.31 |

| TTUFS6.0X40 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X50 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X60 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

| TTUFS6.0X70 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

| TTUFS6.0X80 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

| TTUFS6.0X90 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

| TTUFS6.0X100 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

| TTUFS6.0X120 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

| TTUFS6.0X140 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

| TTUFS6.0X160 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

| TTUFS6.0X180 | 1.08 | 1.31 | 1.31 | 1.08 | 1.36 | 1.36 | 1.08 | 1.41 | 1.41 | 1.35 | 1.56 | 1.56 | 1.35 | 1.64 | 1.64 |

Plywood to Timber Characteristic Capacities

| References | Plywood (ρk≥490 kg/m3) on Timber C24 depending on panel thickness tp | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 [mm] | 15 [mm] | 18 [mm] | 22 [mm] | 25 [mm] | 30 [mm] | |||||||||||||

| Rax.k.10 [kN] | Rv.0.k.10 [kN] | Rv.90.k.10 [kN] | Rax.k.15 [kN] | Rv.0.k.15 [kN] | Rv.90.k.15 [kN] | Rax.k.18 [kN] | Rv.0.k.18 [kN] | Rv.90.k.18 [kN] | Rax.k.22 [kN] | Rv.0.k.22 [kN] | Rv.90.k.22 [kN] | Rax.k.25 [kN] | Rv.0.k.25 [kN] | Rv.90.k.25 [kN] | Rax.k.30 [kN] | Rv.0.k.30 [kN] | Rv.90.k.30 [kN] | |

| TTUFS4.5X50 PT | 0.69 | 0.94 | 0.94 | 0.69 | 1.01 | 1.01 | 0.69 | 1.08 | 1.08 | 1.64 | 1.41 | 1.41 | 1.64 | 1.37 | 1.37 | - | - | - |

| TTUFS5.0X70 | 0.88 | 1.14 | 1.14 | 0.88 | 1.2 | 1.2 | 0.88 | 1.28 | 1.28 | 2.07 | 1.59 | 1.59 | 1.88 | 1.56 | 1.78 | - | - | - |

| TTUFS5.0X80 | 0.88 | 1.14 | 1.14 | 0.88 | 1.2 | 1.2 | 0.88 | 1.28 | 1.28 | 2.07 | 1.59 | 1.59 | 1.88 | 1.56 | 1.78 | - | - | - |

| TTUFS5.0X90 | 0.88 | 1.14 | 1.14 | 0.88 | 1.2 | 1.2 | 0.88 | 1.28 | 1.28 | 2.07 | 1.59 | 1.59 | 1.88 | 1.56 | 1.78 | - | - | - |

| TTUFS5.0X100 | 0.88 | 1.14 | 1.14 | 0.88 | 1.2 | 1.2 | 0.88 | 1.28 | 1.28 | 2.07 | 1.59 | 1.59 | 1.88 | 1.56 | 1.78 | - | - | - |

| TTUFS6.0X40 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X50 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| TTUFS6.0X60 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 2.63 | 2.05 | 2.05 | 2.63 | 2.11 | 2.11 | - | - | - |

| TTUFS6.0X70 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 3 | 2.15 | 2.15 | 3 | 2.25 | 2.25 | - | - | - |

| TTUFS6.0X80 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 3.1 | 2.17 | 2.17 | 3.1 | 2.27 | 2.27 | - | - | - |

| TTUFS6.0X90 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 3.1 | 2.17 | 2.17 | 3.1 | 2.27 | 2.27 | - | - | - |

| TTUFS6.0X100 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 3.1 | 2.17 | 2.17 | 3.1 | 2.27 | 2.27 | - | - | - |

| TTUFS6.0X120 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 3.1 | 2.17 | 2.17 | 3.1 | 2.27 | 2.27 | - | - | - |

| TTUFS6.0X140 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 3.1 | 2.17 | 2.17 | 3.1 | 2.27 | 2.27 | - | - | - |

| TTUFS6.0X160 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 3.1 | 2.17 | 2.17 | 3.1 | 2.27 | 2.27 | - | - | - |

| TTUFS6.0X180 | 1.32 | 1.48 | 1.48 | 1.32 | 1.53 | 1.53 | 1.32 | 1.61 | 1.61 | 3.1 | 2.17 | 2.17 | 3.1 | 2.27 | 2.27 | - | - | - |